- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄2021 > 14242 (Desco)TOOL MICASTAT FLUSH MNT INSERT PDF資料下載

參數(shù)資料

| 型號: | 14242 |

| 廠商: | Desco |

| 文件頁數(shù): | 1/8頁 |

| 文件大小: | 0K |

| 描述: | TOOL MICASTAT FLUSH MNT INSERT |

| 標(biāo)準包裝: | 1 |

| 附件類型: | 安裝工具 |

| 適用于相關(guān)產(chǎn)品: | 嵌入安裝 |

TB-2091 March 2009 Page 1 of 8

TECHNICAL BULLETIN TB-2091

cement, white glue (PVA), epoxy, and hot melt glue. Consult

your adhesive supplier for specific application requirements.

Micastat

is a universal grade laminate for use in general

purpose, postforming and high wear applications.For details

on the installation of Micastat

and other high pressure

laminated plastic sheets refer to National Electrical

Manufacturers Association (NEMA) publication LD 3-1995

or follow these step by step directions for non-postforming

applications.

1. Prepare the face of the substrate. It should be clean, dry

and free of all contaminants which would interfere with

adhesion. Caution should be taken when removing

sheets and pads from its box, sheets and pads are high

pressure laminate plastic and can be susceptible to

cracks and breaking if not conditioned before handling

and installation at 70 to 75deg F and 45-50% RH for 48

hours.

2. Stir the adhesive thoroughly and apply an even coat of

adhesive by either spray, roller or brush to both the

substrate face and the Micastat

back. Do not allow

coated surfaces to touch. Allow the cement to dry. When

bonding to plywood, apply a second coat if the first coat

completely penetrates the wood. Use uncoated wood

strips to assist in connecting coated surfaces.

3. Place thin, uncoated, wooden strips 12 inches apart

across the substrate face. This will keep coated surfaces

apart; bonding will occur once contact is made.

4. Position the over-cut Micastat

sheet on top of the

wooden strips.

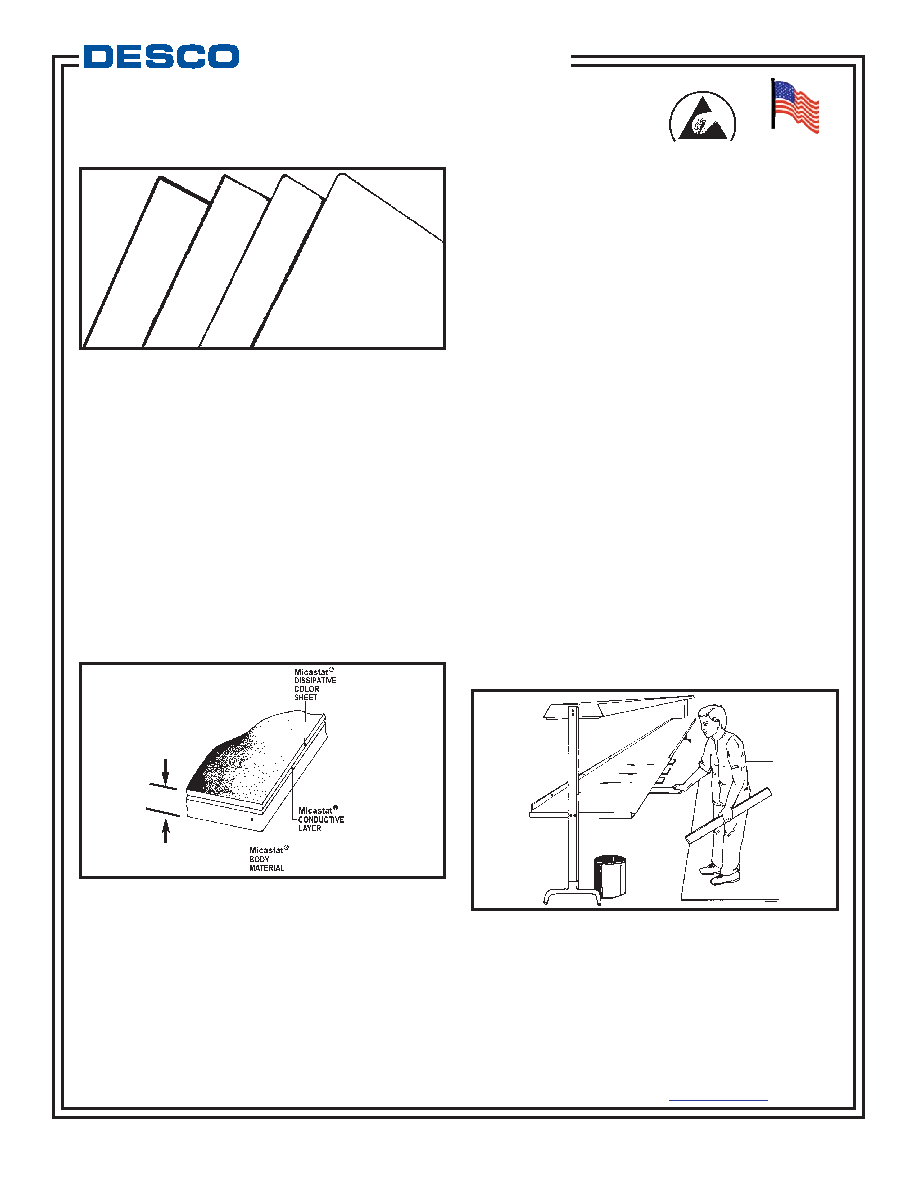

Figure 3. Micastat

sheet on wooden strips

Figure 1. Micastat

Protective Laminate

ESD Blue, ESD Grey, ESD Beige, ESD White

Description

Micastat

is a high pressure static dissipative laminate

designed for workbench tops used in the manufacture and

assembly of ESD susceptible electronic components.

Micastat meets ANSI/ESD S20.20 requiring RTG <109

Ohms per ESD S4.1 and antistatic low tribocharging

materials <200 volts per ESD STM 4.2. Its patented* multi-

layer construction features a conductive layer which

ensures dissipative properties independent of ambient

humidity. Micastat

shows superior abrasion resistance and

provides rapid, non-sparking charge dissipation. It can be

laminated to plywood, fiber board, partical board tables and

bench tops with conventional contact adhesives. It is

resistant to most solvents and greatly exceeds the NEMA

specification for wear resistance.

Figure 2. Micastat

layered construction

Installation

Micastat

is designed to be laminated to wooden tables or

bench tops with conventional contact adhesive and will

perform very well in the most rigorous postforming

applications to a minimum of 5/8" radius. Desco suggests

the use of a high quality solvent or water-based contact

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 (909) 627-8178 Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 (781) 821-8370 Fax (781) 575-0172 Web Site: http://www.desco.com

Micastat

Static Protective Laminate

Installation and Maintenance

0.038

IN.

THICK

*Micastat

is a registered trademark of Desco Industries, Inc.

and is manufactured under one or more of the following U.S.

patents:4,455,350, 4,589,954, 4,645,717, 4,454,199.

2009 DESCO INDUSTRIES, INC.

Employee Owned

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 14401 | WRIST STRAP VINYL DISPOSABLE |

| 14404 | WRIST STRAP DISPOSABLE |

| 14830 | WRIST STRAP ELASTIC W/10' CORD |

| 1501824 | STATIC BAG MET-OUT 18"X24" 100PK |

| 16006X | VINYL DISS BRN VGRV .125 48X40' |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 1424-2 | 功能描述:電路板硬件 - PCB .082 Swage micro pin Tin RoHS:否 制造商:Harwin 類型:Shield Clip 長度:9.4 mm 螺紋大小: 外徑: 材料:Beryllium Copper 電鍍:Tin |

| 14242/000 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:CIRCUIT BOARD FOR PCB PSU'S |

| 1424200 | 功能描述:SENSOR/ACTUATOR FLUSH-TYPE PLG 1 制造商:phoenix contact 系列:* 零件狀態(tài):在售 標(biāo)準包裝:20 |

| 14242-000 | 制造商:VXI POWER 功能描述:PCB FOR VXI 5W PSUS |

| 1424201 | 功能描述:SENSOR/ACTUATOR FLUSH-TYPE SOCKE 制造商:phoenix contact 系列:* 零件狀態(tài):在售 標(biāo)準包裝:20 |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。