- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄65800 > MA4PBL027 SILICON, PIN DIODE PDF資料下載

參數(shù)資料

| 型號: | MA4PBL027 |

| 元件分類: | PIN二極管 |

| 英文描述: | SILICON, PIN DIODE |

| 封裝: | CASE ODS-1302, 2 PIN |

| 文件頁數(shù): | 2/5頁 |

| 文件大小: | 309K |

| 代理商: | MA4PBL027 |

HMICTM Silicon Beam-Lead PIN Diodes

M/A-COM Inc. and its affiliates reserve the right to make changes to the

product(s) or information contained herein without notice. M/A-COM makes

no warranty, representation or guarantee regarding the suitability of its

products for any particular purpose, nor does M/A-COM assume any liability

whatsoever arising out of the use or application of any product(s) or

information.

North America Tel: 800.366.2266 / Fax: 978.366.2266

Europe Tel: 44.1908.574.200 / Fax: 44.1908.574.300

Asia/Pacific Tel: 81.44.844.8296 / Fax: 81.44.844.8298

Visit www.macom.com for additional data sheets and product information.

2

V1

MA4PBL027

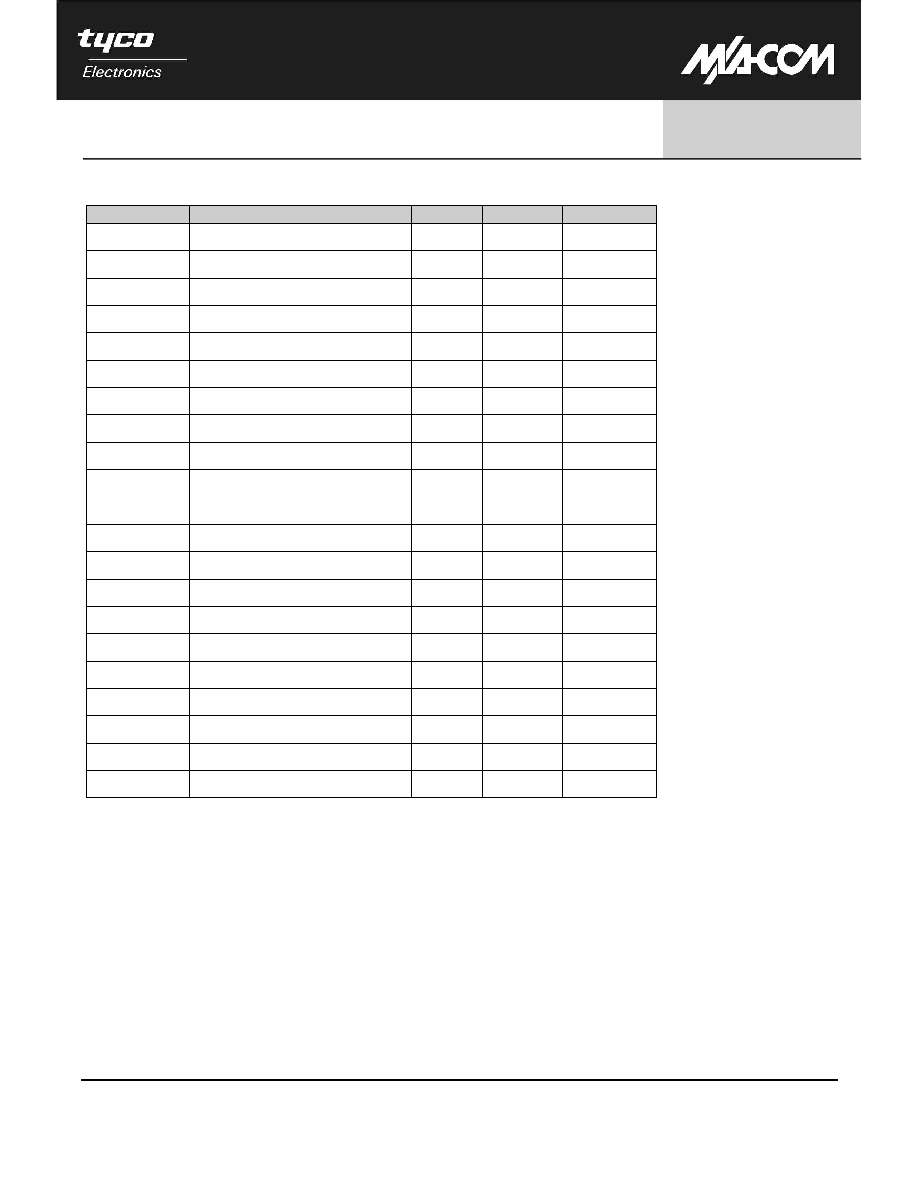

Electrical Specifications at +25 °C

Symbol

Conditions

Units

Typ.

Max.

CT

0 V, 1 MHz

2

pF

0.048

CT

-3 V, 1 MHz

2

pF

0.039

CT

-10 V, 1 MHz

2

pF

0.033

0.040

CT

-40 V, 1 MHz

2

pF

0.030

0.040

CT

0 V, 100 MHz

2,4

pF

0.043

CT

-3 V, 100 MHz

2,4

pF

0.033

CT

-10V, 100 MHz

2,4

pF

0.031

CT

-40V, 100 MHz

2,4

pF

0.027

CT

0 V, 1 GHz

2,4

pF

0.039

CT

-3 V, 1 GHz

2,4

pF

0.032

CT

-10 V, 1 GHz

2,4

pF

0.029

CT

-40 V, 1 GHz

2,4

pF

0.026

RS

10 mA, 100 MHz

3,4

3.8

RS

20 mA, 100 MHz

3,4

3.0

RS

10 mA, 1 GHz

3,4

3.5

RS

20 mA, 1 GHz

3,4

2.8

VF

20 mA

V

0.917

1.1

VR

-10

A

V

110

IR

-40 V

nA

1.0

IR

-90 V

uA

-

10.0

TL

+10 mA / -6 mA

ns

110

2. Total capacitance,

CT, is equivalent to the sum of Junction Capacitance ,Cj, and Parasitic Capacitance, Cpar.

3. Series resistance RS is equivalent to the total diode resistance : Rs = Rj ( Junction Resistance) + Rc ( Ohmic Resistance)

4. Rs and CT are measured on an HP4291A Impedance Analyzer with die mounted in an ODS-186 package with conductive silver epoxy.

NOTES:

Die Handling

All semiconductor chips should be handled with care

to avoid damage or contamination from perspiration

and skin oils. The use of plastic tipped tweezers or

vacuum

pickups

is

strongly

recommended

for

individual components. Bulk handling should insure

that abrasion and mechanical shock are minimized.

Die Bonding

These devices were designed to be inserted onto

hard or soft substrates. Recommended methods of

attachment include thermocompression bonding, par-

allel-gap welding, and electrically conductive silver epoxy.

See

Application

Note

M541,

“Bonding

and

Handling Procedures for Chip Diode Devices” for

More Detailed Assembly Instructions.

相關PDF資料 |

PDF描述 |

|---|---|

| MA4ST1320-1279T | 55 pF, 12 V, SILICON, HYPERABRUPT VARIABLE CAPACITANCE DIODE |

| MA4ST350-287 | S BAND, 11.8 pF, 12 V, SILICON, HYPERABRUPT VARIABLE CAPACITANCE DIODE |

| MA4ST340-287 | S BAND, 18.5 pF, 12 V, SILICON, HYPERABRUPT VARIABLE CAPACITANCE DIODE |

| MA4X7130G | MIXER DIODE |

| MA652 | 20 A, 200 V, SILICON, RECTIFIER DIODE, TO-220AB |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| MA4PH151 | 制造商:MA-COM 制造商全稱:M/A-COM Technology Solutions, Inc. 功能描述:Surface Mount Plastic PIN Diodes |

| MA4PH151-139T | 制造商:M/A-COM Technology Solutions 功能描述:AXIAL LEAD PIN DIODE - Tape and Reel 制造商:M/A-COM Technology Solutions 功能描述:RF PIN DIODE |

| MA4PH152-1072 | 制造商:M/A-COM Technology Solutions 功能描述:SPECIAL PRODUCT - Bulk |

| MA4PH152-1072T | 制造商:M/A-COM Technology Solutions 功能描述:SPECIAL PRODUCT - Tape and Reel |

| MA4PH235 | 制造商:M/A-COM TECHNOLOGY SOLUTI 功能描述: 制造商:MA-COM 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復。