- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄358625 > 3224W-1-102E TRIMMER SMD CERMET MEHR 1K 300V 0.25W PDF資料下載

參數(shù)資料

| 型號(hào): | 3224W-1-102E |

| 英文描述: | TRIMMER SMD CERMET MEHR 1K 300V 0.25W |

| 中文描述: | 修邊機(jī)表面貼裝金屬陶瓷伊朗Mehr一千300V 0.25W |

| 文件頁數(shù): | 54/86頁 |

| 文件大?。?/td> | 3230K |

| 代理商: | 3224W-1-102E |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁當(dāng)前第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁第85頁第86頁

Specifications are subject to change without notice.

58

Features

I

Surface Mount / Single-Turn Cermet /

Process Sealed

I

Elastomer seal allows multiple

adjustments (5 rotations)

I

Compatible with all surface mount

manufacturing processes

I

Recommended for reflow processing only

3374 - 4mm Square Trimming Potentiometer

I

Cross-slot rotor design suitable for

automatic adjustment equipment

I

Supplied in 12mm embossed tape,

compatible with automatic pick-and-place

assembly equipment

I

Patent #5,095,298

I

Plastic rotor minimizes RF & ESD

concerns

Electrical Characteristics

Standard Resistance Range

..................................10 to 2 megohms

(see standard resistance table)

Resistance Tolerance .............±20% std.

End Resistance........1% or 2 ohms max.

(whichever is greater)

Contact Resistance Variation

..............................3% or 3 ohms max.

(whichever is greater)

Resolution.....................................Infinite

Adjustment Angle ...................240o nom.

Maximum Voltage ...........................200V

Environmental Characteristics

Power Rating

70°C.......................................0.25 watt

125°C..........................................0 watt

Operating Temperature Range

...................................-55°C to +125°C

Temperature Coefficient

<500K ohms.....................±100ppm/°C

≥

500K ohms.....................±150ppm/°C

Seal......................................5 turns min.

Humidity........MIL-STD 202 Method 103

Vibration........20G; TRS ±1%, VRS ±1%

Shock..........100G; TRS ±1%, VRS ±1%

Load Life (@70oC Rated Power,

1000 hours)...........................TRS ±3%

Rotational Life ......100 cycles; TRS ±3%

Thermal Shock...........................5 cycles

TRS ±2%, VRS ±1%

Physical Characteristics

Torque.............................18 - 180gm/cm

Mechanical Angle .................Continuous

Marking..........Manufacturer’s trademark

and part marking code

Wiper ..........Positioned at 50% nominal

Standard Packaging ......750 pcs./7” reel

Adjustment Tool ..............................H-90

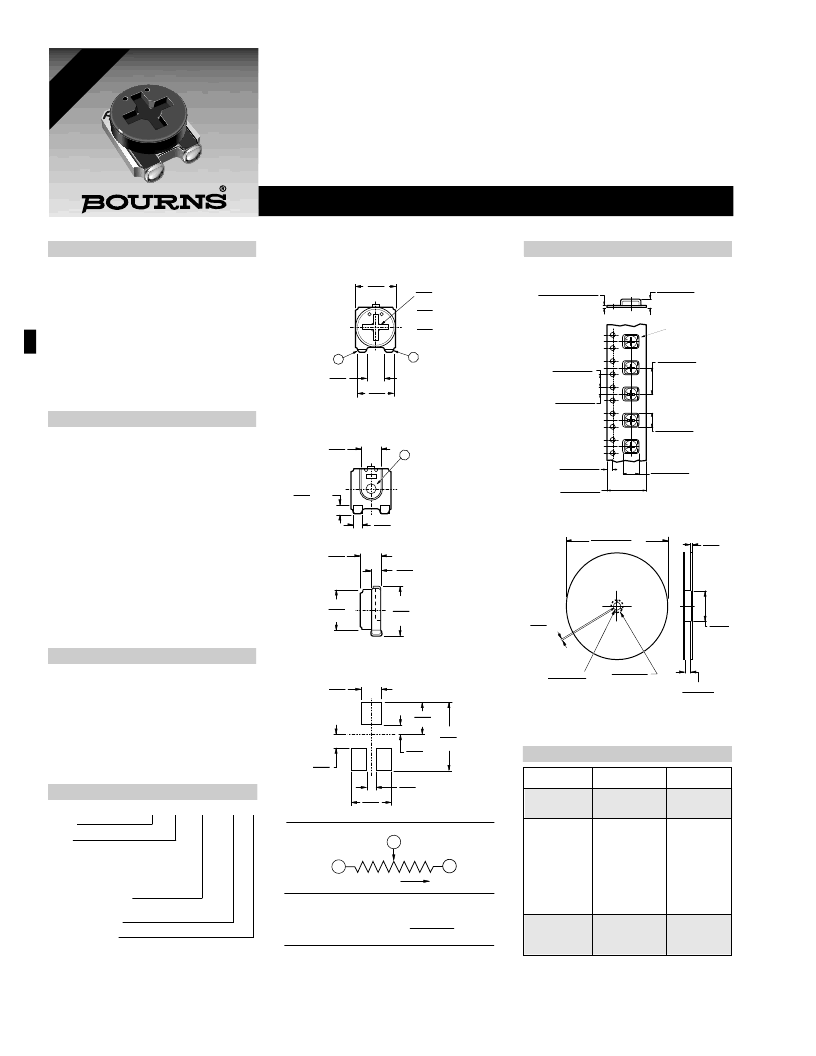

1.40

(.055)

.99

(.039)

3.99

(.157)

.99

(.039)

3.17

(.125)

6.78

(.267)

1.98

(.078)

1

3

CW

CLOCKWISE

CCW

2

WIPER

3

4.01

(.158)

1.78

(.070)

3.56

(.140)

1

1.93

(.076)

2

4.90

(.193)

1.97

(.078)

.76

(030)

3.96

(.156)

0.74

(.029)

0.61

(.024)

ADJ. SLOT

.48

(.019)

.38

(.015)

2.54

(.100)

2 PLCS.

WIDE

X

X

DEEP

LONG

MAX.

TYP. 2 PLCS.

TYP.

2 PLCS.

8.00

±

.10

(.315

±

.004)

4.29

±

.20

(.169

±

.008)

12.00

±

.30

(.472

±

.012)

1.75

±

.10

(.069

±

.004)

2.00

±

.05

(.079

±

.002)

3.98

±

.10

(.157

±

.004)

5.00

±

.20

(.197

±

.008)

2.69

±

.20

(.106

±

.008)

.30 + .025/- .076

(.012 + .001/- .003)

MAX.

X Orientation Shown

Packaging Specifications

Standard Resistance Table

Popular values listed in boldface. Special

resistances available.

SHADED AREAS TYPICALLY NOT STOCKED BY

DISTRIBUTORS AND NOT RECOMMENDED FOR NEW

DESIGNS.

How To Order

3374 X - 1 - 502 E

Model

Style

Orientation of Parts in Tape:

Style W - Terminals Toward

Sprocket Holes

Standard or Modified

Product Indicator

-1 = Standard Product

Resistance Code

Embossed Tape

750 pcs./7” reel (standard)

Consult factory for other available options.

3374X/W

21.01

±

.76

(.827

±

.030)

DIA.

13.0

±

.50

(.512

±

.020)

DIA.

177.8

±

2.03

(7.000

±

.080)

EQUAL

SPACED

3 PLCS.

1.73

(.068)

14.0

±

1.5

(.551

±

.59)

2.0

(.079)

REF.

59.2

(2.331)

REF.

DIA.

MIN.

TAPE

REEL

Meets EIA 481

Resistance

(Ohms)

10

20

50

100

200

500

1,000

2,000

5,000

10,000

20,000

50,000

100,000

200,000

500,000

1,000,000

2,000,000

Part Marking

Code

A1

21

51

A2

22

52

A3

23

53

A4

24

54

A5

25

55

A6

26

Resistance

Code

100

200

500

101

201

501

102

202

502

103

203

503

104

204

504

105

205

THOUGH

DSTRBUION

DIMENSIONS ARE:

METRIC

(INCHES)

TOLERANCES: ±0.25 (.010) EXCEPT WHERE NOTED

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 3386H-1-504 | TRIMMER 11MM CERMET EIN 500K 300V 0.5W |

| 322CNQ030 | 300 Amp Schottky Rectifier(300 A 肖特基整流器) |

| 3239-00 | 2.2 GHz Integer-N PLL for Low Phase Noise Applications |

| 323GT | 5.0mm Round Type LED Lamps |

| 3245A-MSOP8 | Constant Current Forward/Reverse Driver IC for Digital Cameras |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 3224W-1-102E | 制造商:Bourns Inc 功能描述:Trimmer |

| 3224W-1-102E | 制造商:Bourns Inc 功能描述:TRIMMER 0.25W 1K 制造商:Bourns Inc 功能描述:TRIMMER, 0.25W, 1K |

| 3224W-1-102G | 功能描述:微調(diào)電阻器 - 表面貼裝 4mm 1Kohms 10% Square Cermet Sealed RoHS:否 制造商:Murata 產(chǎn)品:Single-Turn Trimmer Potentiometers 產(chǎn)品類型:Single Turn 轉(zhuǎn)數(shù):1 元件類型:Cermet 錐度:Linear 電阻:10 kOhms 電壓額定值: 端接類型:SMD/SMT 功率額定值:250 mW (1/4 W) 容差:20 % 溫度系數(shù):150 PPM / C |

| 3224W1103E | 制造商:Bourns / JW Miller 功能描述:Res Cermet Trimmer 10K Ohm 10% 1/4W 12(Elec)Turn 1.5mm (4.8 X 3.9 X 5.3mm) J-Hook SMD Embossed T/R 制造商:Bourns 功能描述:Res Cermet Trimmer 10K Ohm 10% 1/4W 12(Elec)Turn 1.5mm (4.8 X 3.9 X 5.3mm) J-Hook SMD Embossed T/R |

| 3224W-1-103E | 功能描述:微調(diào)電阻器 - 表面貼裝 4mm 10Kohms 10% Square Cermet Sealed RoHS:否 制造商:Murata 產(chǎn)品:Single-Turn Trimmer Potentiometers 產(chǎn)品類型:Single Turn 轉(zhuǎn)數(shù):1 元件類型:Cermet 錐度:Linear 電阻:10 kOhms 電壓額定值: 端接類型:SMD/SMT 功率額定值:250 mW (1/4 W) 容差:20 % 溫度系數(shù):150 PPM / C |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。