- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄297490 > T5323-1M (VALPEY FISHER CORP) CRYSTAL OSCILLATOR, CLOCK, 1 MHz, HCMOS OUTPUT PDF資料下載

參數(shù)資料

| 型號(hào): | T5323-1M |

| 廠商: | VALPEY FISHER CORP |

| 元件分類: | XO, clock |

| 英文描述: | CRYSTAL OSCILLATOR, CLOCK, 1 MHz, HCMOS OUTPUT |

| 封裝: | ROHS COMPLIANT, HERMETIC SEALED, CERAMIC, SMD, LCC-4 |

| 文件頁(yè)數(shù): | 2/6頁(yè) |

| 文件大小: | 250K |

| 代理商: | T5323-1M |

75 South Street, Hopkinton, MA 01748 800-982-5737 508-435-6831 FAX 508-435-5289 www.valpeyfisher.com RevE0910

2

T5321 Series

T5421 Series

5 x 7 mm Surface Mount High Reliability

Tristate/Non-Tristate, 1MHz to 100MHz

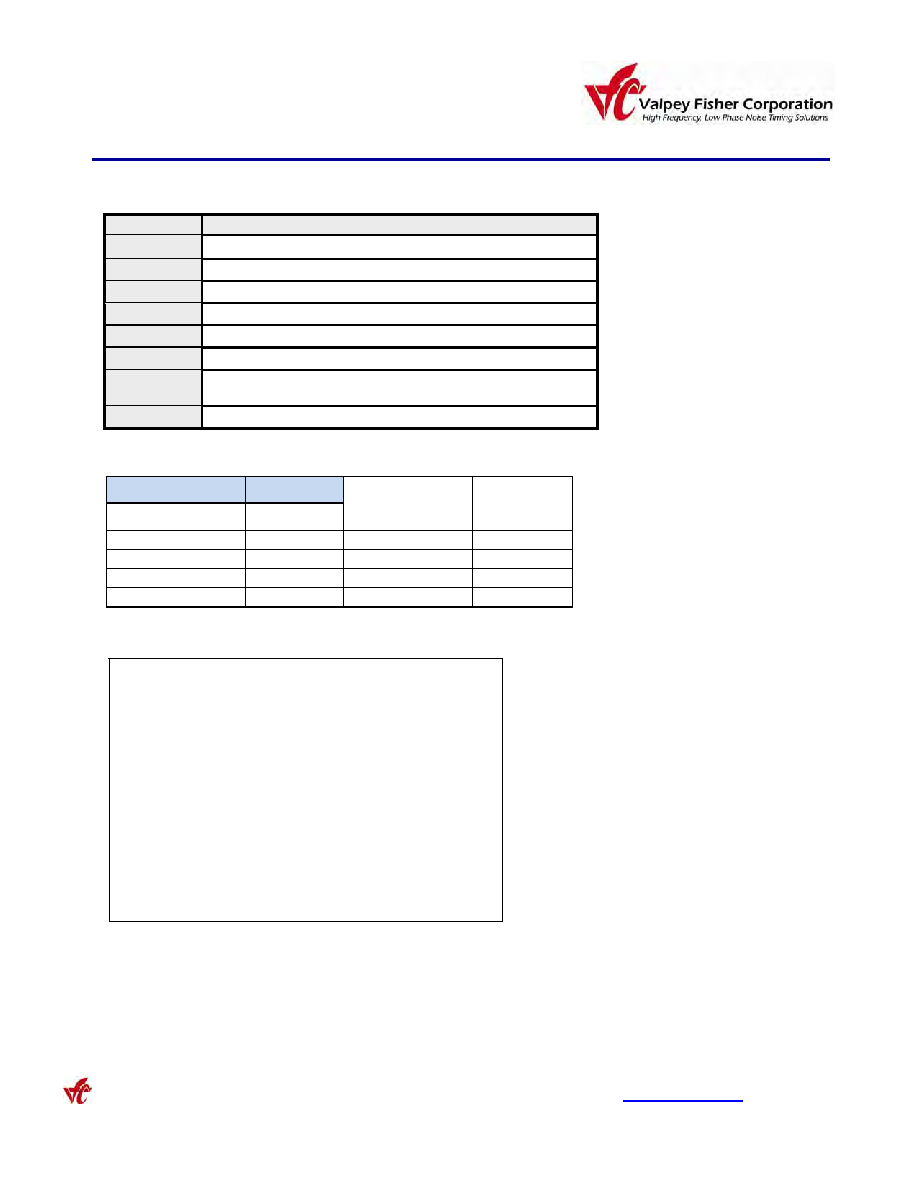

Parameter

Condition

Shock

1000 Gs, 0.35 ms, sine wave, 3 shocks in each plane

Vibration

10-2000 Hz of .06” d.a. or 20Gs, whichever is less

Humidity

Resistant to 85° R.H. at 85°C

Leak

Per MIL-STD-883, Method 1014, Cond. A1 and C1

Case

Hermetically sealed ceramic LCC

Pads

40 microinch of gold over nickel

Resistance

to Solvents

Per MIL-STD-202, Method 215

Marking

Epoxy ink or laser engraved

FIXED OUTPUT

TRISTATE

Operating

Temperature

Frequency

Stability

Model

T5321

T5421

-55

C to +85C

±25 ppm

T5322

T5422

-55

C to +85C

±50 ppm

T5323

T5423

-55

C to +125C

±75 ppm

T5324

T5424

-55

C to +125C

±50 ppm

Environmental and Mechanical Conditions

Thermal Characteristics

Thermal Resistance

From Junction to Case, Rjc

16 °C/Watt

Surface Mount Application

These packages are designed for reflow soldering

in accordance with recommended profiles. For

hand-soldering, the temperature of the iron should

not exceed 400°C for three seconds.

Table 1

Each unit undergoes the following:

1. Stabilization Bake

MIL-STD-883 Method 1008, Cond,.B

2. Temperature Cycling

MIL-STD-883 Method 1010, Cond, B

3. Constant Acceleration

MIL-STD-883 Method 2001, Cond, A

4. Burn-in

MIL-STD-883 Method 1015, Cond B

(125°C for 168 hours with bias)

5. Fine Leak

MIL-STD-883 Method 1014, Cond. A1

6. Gross Leak

MIL-STD-883 Method 1014, Cond C

7. Electrical Test at 25°C and temperature extremes, as follows:

A. Frequency

F. Duty Cycle

B. Current

G. Frequency at 3.65V

C. Rise Time

H. Frequency at 3.0V

D. Fall Time

I. “Zero” logic level

E. Duty Cycle

J. “One” logic level

K. Tristate

Test Data on each unit is available for additional cost

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| T5623-32M | CRYSTAL OSCILLATOR, CLOCK, 32 MHz, HCMOS OUTPUT |

| T5724-40M | CRYSTAL OSCILLATOR, CLOCK, 40 MHz, HCMOS OUTPUT |

| T630 | Radiation hard 16-Bit ParallelError Detection & Correction |

| T6A6CI | Bi-Directional Triode Thyristor 6A Mold TRIAC |

| T70HFL10S10 | 70 A, 100 V, SILICON, RECTIFIER DIODE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| T532N | 制造商:Apex Tool Group 功能描述:CUTTER 5" DIAG MED OVAL HD SUP |

| T5331 | 制造商:TE Connectivity 功能描述: |

| T5333 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:TRIANGULAR TYPE |

| T5337 | 制造商:TE Connectivity 功能描述: |

| T5338 | 制造商:TE Connectivity 功能描述: |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。