- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄382347 > MR760RLG (ON SEMICONDUCTOR) High Current Lead Mounted Rectifiers PDF資料下載

參數(shù)資料

| 型號: | MR760RLG |

| 廠商: | ON SEMICONDUCTOR |

| 元件分類: | 參考電壓二極管 |

| 英文描述: | High Current Lead Mounted Rectifiers |

| 中文描述: | 6 A, 1000 V, SILICON, RECTIFIER DIODE |

| 封裝: | LEAD FREE, PLASTIC, CASE 194-04, 2 PIN |

| 文件頁數(shù): | 4/7頁 |

| 文件大小: | 104K |

| 代理商: | MR760RLG |

MR750 SERIES

http://onsemi.com

4

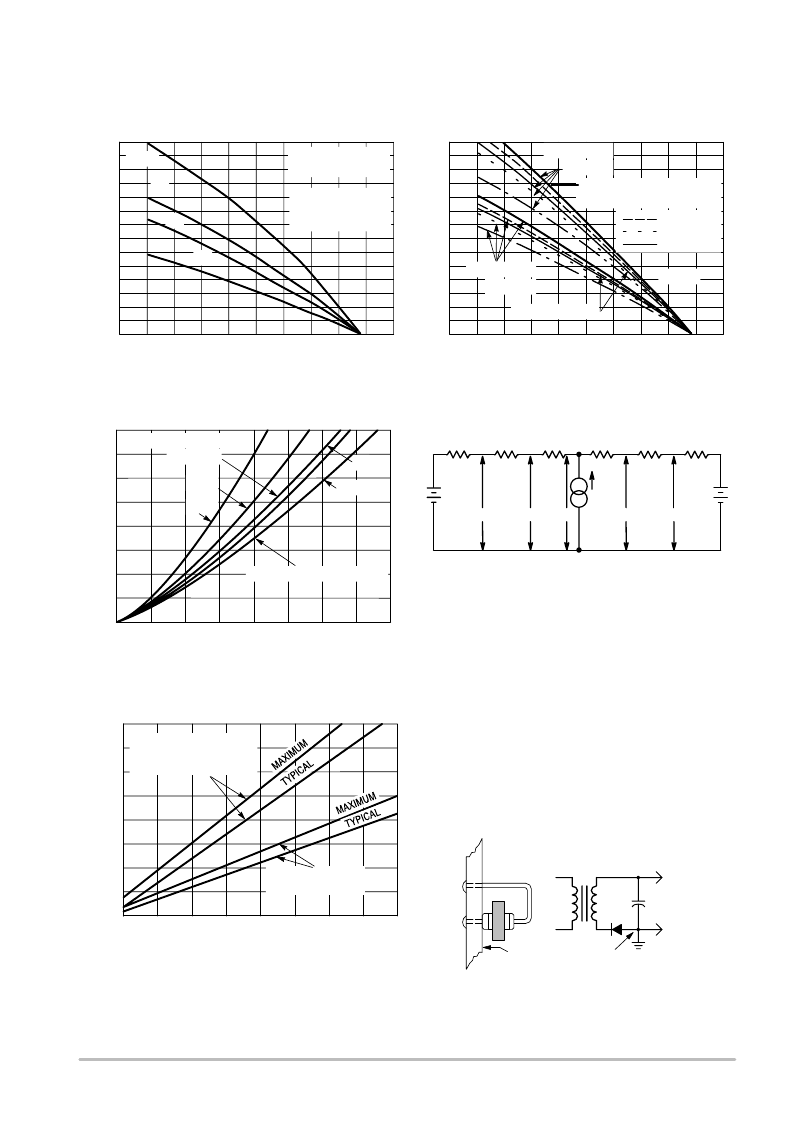

Figure 5. Maximum Current Ratings

T

L

, LEAD TEMPERATURE (

°

C)

0

8.0

I

0

12

20

28

40

80

120

160

200

Figure 6. Maximum Current Ratings

0

8.0

4.0

0

16

24

32

I

F(AV)

, AVERAGE FORWARD CURRENT (AMPS)

Figure 7. Power Dissipation

PF

,

5/8"

,

CAPACITANCE LOADS

8.0

12

16

RESISTIVE INDUCTIVE

LOADS

T

A

, AMBIENT TEMPERATURE (

°

C)

0

1.0

I

0

2.0

3.0

4.0

40

80

120

160

200

Figure 8. Steady State Thermal Resistance

f = 60 Hz

,

RESISTIVE INDUCTIVE LOADS

CAPACITANCE LOADS 1

& 3

20

6

1 & 3

20 I

avg

T

A(A)

T

A(K)

T

L(A)

T

C(A)

T

J

T

C(K)

T

L(K)

P

F

R

S(A)

R

L(A)

R

J(A)

R

J(K)

R

L(K)

R

S(K)

Use of the above model permits junction to lead thermal resistance for

any mounting configuration to be found. Lowest values occur when one

side of the rectifier is brought as close as possible to the heat sink as

shown below. Terms in the model signify:

T

A

= Ambient Temperature

T

L

= Lead Temperature

R

S

= Thermal Resistance, Heat Sink to Ambient

R

L

= Thermal Resistance, Lead to Heat Sink

R

J

= Thermal Resistance, Junction to Case

P

F

= Power Dissipation

(Subscripts A and K refer to anode and cathode sides, respectively.)

Values for thermal resistance components are:

R

L

= 40

°

C/W/in. Typically and 44

°

C/W/in Maximum.

R

J

= 2

°

C/W typically and 4

°

C/W Maximum.

Since R

J

is so low, measurements of the case temperature, T

C

, will be

approximately equal to junction temperature in practical lead mounted

applications. When used as a 60 Hz rectifierm the slow thermal response

holds T

J(PK)

close to T

J(AVG)

. Therefore maximum lead temperature may

be found from: T

L

= 175

R

JL

P

F

. P

F

may be found from Figure 7.

The recommended method of mounting to a P.C. board is shown on the

sketch, where R

JA

is approximately 25

°

C/W for a 11/2" x 11/2" copper

surface area. Values of 40

°

C/W are typical for mounting to terminal strips

or P.C. boards where available surface area is small.

T

C

= Case Temperature

T

J

= Junction Temperature

éé

éé

éé

éé

éé

éé

éé

Board Ground Plane

24

28

32

0

1/4

5.0

0

1/2

3/4

1.0

L, LEAD LENGTH (INCHES)

θ

SINGLE LEAD TO HEAT SINK,

INSIGNIFICANT HEAT FLOW

THROUGH OTHER LEAD

10

15

20

25

30

35

40

24

16

4.0

20

60

100

140

180

4.0

12

20

28

1/8

3/8

5/8

7/8

J

°

BOTH LEADS TO HEAT

SINK WITH LENGTHS

AS SHOWN

3/8"

1/4"

L = 1/8"

20

60

100

140

180

5.0

6.0

7.0

I

(pk)

= 5 I

avg

I

(pk)

= 10 I

avg

I

(pk)

= 20 I

avg

10 I

avg

I

(pk)

= 5 I

avg

RESISTIVE INDUCTIVE LOADS

BOTH LEADS TO HEAT

SINK, EQUAL LENGTH

6 (I

PK

/I

AVE

= 6.28)

SEE NOTE

R

JA

= 40

°

C/W

SEE NOTE

R

JA

= 25

°

C/W

NOTES

THERMAL CIRCUIT MODEL

(For Heat Conduction Through The Leads)

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MR750RL | High Current Lead Mounted Rectifiers |

| MR750RLG | High Current Lead Mounted Rectifiers |

| MR751G | High Current Lead Mounted Rectifiers |

| MR751RL | High Current Lead Mounted Rectifiers |

| MR751RLG | High Current Lead Mounted Rectifiers |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MR77 | 制造商:FLIR COMMERCIAL SYSTEMS 功能描述:Moisture Meter, IR, Bluetooth 制造商:FLIR SYSTEMS 功能描述:TEST, 0% TO 99.9%, Moisture Content:0% to 99.9% , RoHS Compliant: Yes |

| MR-776 | 制造商:Commscope Inc 功能描述: |

| MR77B3 028309 | 制造商:Comair Rotron 功能描述:FAN 172MM 230VAC |

| MR77B3 | 制造商:Comair Rotron 功能描述:FAN 171MM 230VAC |

| MR78700 | 制造商:TE Connectivity 功能描述: 制造商:TE Connectivity / Schrack Brand 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。