- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄98028 > MPQ6002 (ON SEMICONDUCTOR) 0.5 A, 30 V, 4 CHANNEL, NPN AND PNP, Si, POWER TRANSISTOR, TO-116 PDF資料下載

參數(shù)資料

| 型號: | MPQ6002 |

| 廠商: | ON SEMICONDUCTOR |

| 元件分類: | 功率晶體管 |

| 英文描述: | 0.5 A, 30 V, 4 CHANNEL, NPN AND PNP, Si, POWER TRANSISTOR, TO-116 |

| 封裝: | PLASTIC, DIP-14 |

| 文件頁數(shù): | 25/34頁 |

| 文件大小: | 333K |

| 代理商: | MPQ6002 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁當前第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁

9–19

Reliability and Quality Assurance

Motorola Small–Signal Transistors, FETs and Diodes Device Data

147

148

149

150

151

152

153

154

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39 40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

0

1

2

3

4

5

6

7

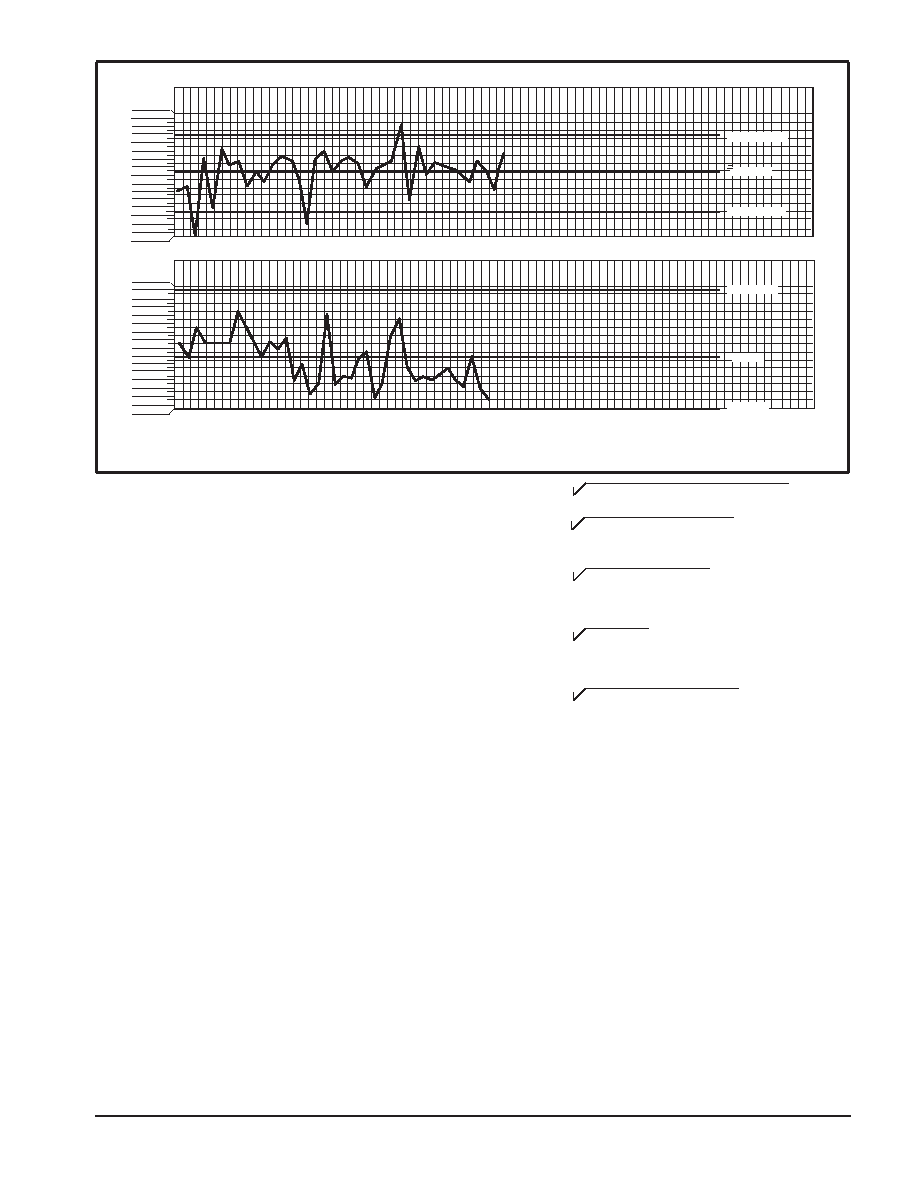

UCL = 152.8

= 150.4

LCL = 148.0

UCL = 7.3

= 3.2

LCL = 0

X

R

Figure 4. Example of Process Control Chart Showing Oven Temperature Data

Where D4, D3, and A2 are constants varying by sample size,

with values for sample sizes from 2 to 10 shown in the

following partial table:

n234

56789

10

D4

3.27

2.57

2.28

2.11

2.00

1.92

1.86

1.82

1.78

D3

*

0.08

0.14

0.18

0.22

A2

1.88

1.02

0.73

0.58

0.48

0.42

0.37

0.34

0.31

*For sample sizes below 7, the LCLR would technically be a negative number;

in those cases there is no lower control limit; this means that for a subgroup size

6, six ‘‘identical’’ measurements would not be unreasonable.

Control charts are used to monitor the variability of critical

process parameters. The R chart shows basic problems with

piece to piece variability related to the process. The X chart can

often identify changes in people, machines, methods, etc. The

source of the variability can be difficult to find and may require

experimental design techniques to identify assignable causes.

Some general rules have been established to help determine

when a process is OUT–OF–CONTROL. Figure 5 shows a

control chart subdivided into zones A, B, and C corresponding

to 3 sigma, 2 sigma, and 1 sigma limits respectively. In Figures

6 through 9 four of the tests that can be used to identify

excessive variability and the presence of assignable causes

are shown. As familiarity with a given process increases, more

subtle tests may be employed successfully.

Once the variability is identified, the cause of the variability

must be determined. Normally, only a few factors have a

significant impact on the total variability of the process. The

importance of correctly identifying these factors is stressed in

the following example. Suppose a process variability depends

on the variance of five factors A, B, C, D, and E. Each has a

variance of 5, 3, 2, 1, and 0.4, respectively.

Since:

σ tot =

σ A2 + σ B2 + σ C2 + σ D2 + σ E2

σ tot =

52 + 32 + 22 + 12 +(0.4)2 = 6.3

If only D is identified and eliminated, then:

σ tot =

52 + 32 + 22 + (0.4)2 = 6.2

This results in less than 2% total variability improvement. If

B, C, and D were eliminated, then:

σ tot =

52 + (0.4)2 = 5.02

This gives a considerably better improvement of 23%. If

only A is identified and reduced from 5 to 2, then:

σ tot =

22 + 32 + 22 + 12 + (0.4)2 = 4.3

Identifying and improving the variability from 5 to 2 yields a

total variability improvement of nearly 40%.

Most techniques may be employed to identify the primary

assignable cause(s). Out–of–control conditions may be

correlated to documented process changes. The product may

be analyzed in detail using best versus worst part comparisons

or Product Analysis Lab equipment. Multi–variance analysis

can be used to determine the family of variation (positional,

critical, or temporal). Lastly, experiments may be run to test

theoretical or factorial analysis. Whatever method is used,

assignable causes must be identified and eliminated in the

most expeditious manner possible.

After assignable causes have been eliminated, new control

limits are calculated to provide a more challenging variablility

criteria for the process. As yields and variability improve, it may

become more difficult to detect improvements because they

become much smaller. When all assignable causes have been

eliminated and the points remain within control limits for 25

groups, the process is said to in a state of control.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MPQ6502 | 0.5 A, 30 V, 4 CHANNEL, NPN AND PNP, Si, POWER TRANSISTOR, TO-116 |

| MPQ6426 | 500 mA, 30 V, 4 CHANNEL, NPN, Si, SMALL SIGNAL TRANSISTOR, TO-116 |

| MPQ6600A1 | 50 mA, 45 V, 4 CHANNEL, NPN AND PNP, Si, SMALL SIGNAL TRANSISTOR, TO-116 |

| MPQ6842 | 200 mA, 30 V, 4 CHANNEL, NPN AND PNP, Si, SMALL SIGNAL TRANSISTOR, TO-116 |

| MPQ7043 | 0.5 A, 250 V, 4 CHANNEL, NPN, Si, POWER TRANSISTOR, TO-116 |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MPQ6002N | 制造商:MOTOROLA 制造商全稱:Motorola, Inc 功能描述:QUAD DUAL IN LINE SILICON COMPLEMENTARY PAIR TRANSISTORS |

| MPQ6100A | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| MPQ6400 | 制造商:MPS 制造商全稱:Monolithic Power Systems 功能描述:Low Quiescent Current Programmable-Delay Supervisory Circuit |

| MPQ6400DG-33 | 制造商:MPS 制造商全稱:Monolithic Power Systems 功能描述:Low Quiescent Current Programmable-Delay Supervisory Circuit |

| MPQ6400DG-33-AEC1 | 制造商:MPS 制造商全稱:Monolithic Power Systems 功能描述:Low Quiescent Current Programmable-Delay Supervisory Circuit |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。