- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄383574 > MCH15 (Rohm CO.,LTD.) Multi-layer Ceramic Chip Capacitors(多層陶瓷電容) PDF資料下載

參數(shù)資料

| 型號: | MCH15 |

| 廠商: | Rohm CO.,LTD. |

| 英文描述: | Multi-layer Ceramic Chip Capacitors(多層陶瓷電容) |

| 中文描述: | 多層陶瓷芯片電容器(多層陶瓷電容) |

| 文件頁數(shù): | 4/10頁 |

| 文件大小: | 119K |

| 代理商: | MCH15 |

MCH15

Ceramic capacitors

!

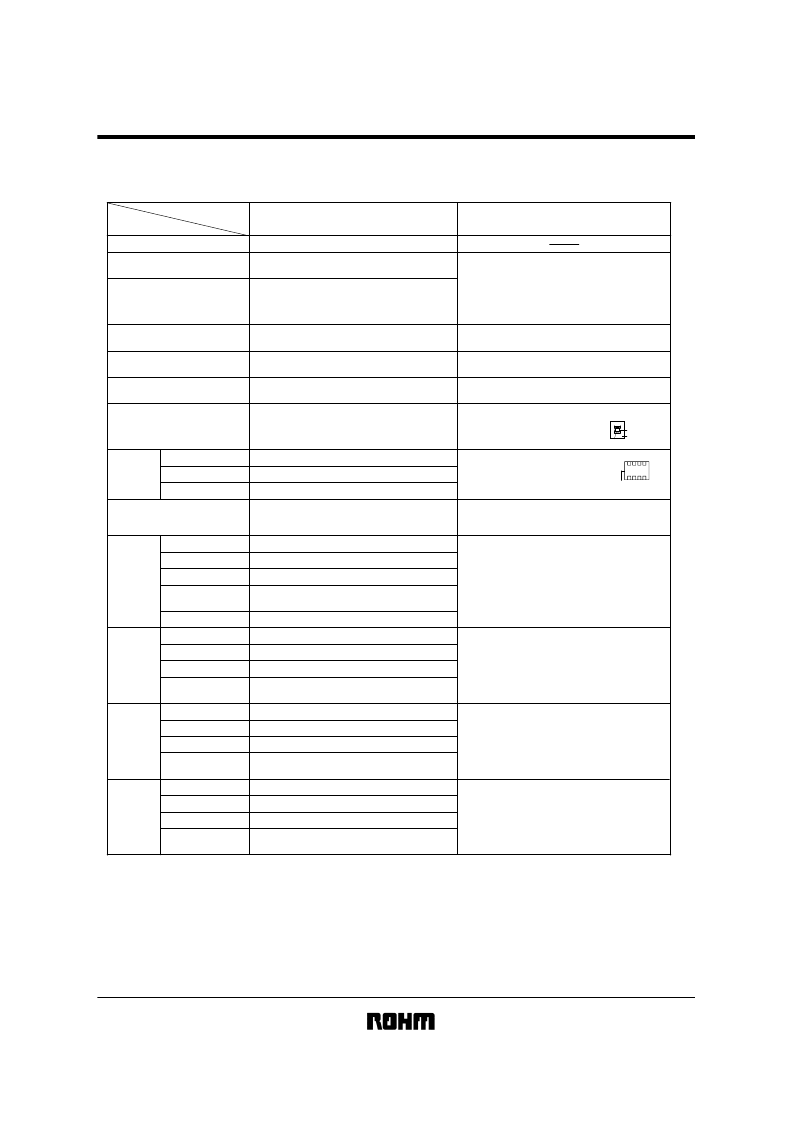

Characteristics

A (C0G)

-55

C ~

125

C

Temperature characteristics

Item

Operating temperature

Nominal capacitance (C)

Dissipation factor (tan

δ

)

Insulation resistance (IR)

Withstanding voltage

Temperature characteristics

Terminal adherence

Resistance

to vibration

Solderability

Resistance

to soldering

heat

Temperature

cycling

High-

temperature

load test

Humidity load

test

Must be within the specified tolerance range.

100/(400+20C)% or less: Less than 30 pF

0.1% or less: 30 pF or larger

10,000 M

or 500 M

μ

F,

whichever is smaller

The insulation must not be damaged.

Within 0

±

30ppm/

C

No detachment or signs of detachment.

There must be no mechanical damage.

Must be within initial tolerance.

Must satisfy initial specified value.

At least 3/4 of the surface of the two terminals

must be covered with new solder.

There must be no mechanical damage.

±

2.5% or

±

0.25 pF, whichever is larger.

Must satisfy initial specified value.

10,000 M

or 500 M

μ

F,

whichever is smaller

The insulation must not be damaged.

There must be no mechanical damage.

±

2.5% or

±

0.25 pF, whichever is larger.

Must satisfy initial specified value.

10,000 M

or 500 M

μ

F,

whichever is smaller

There must be no mechanical damage.

±

7.5% or

±

0.75 pF, whichever is larger.

0.5% or less

500 M

or 25 M

μ

F,

whichever is smaller

There must be no mechanical damage.

1,000 M

or 50 M

μ

F,

whichever is smaller

±

3.0% or

±

0.3 pF, whichever is larger.

0.3% or less

Appearance

Rate of capacitance change

tan

δ

Appearance

Rate of capacitance change

tan

δ

Insulation resistance

Withstanding voltage

Appearance

Rate of capacitance change

tan

δ

Insulation resistance

Appearance

Rate of capacitance change

tan

δ

Insulation resistance

Appearance

Rate of capacitance change

tan

δ

Insulation resistance

Test methods/conditions

(based on JIS C 5102)

Based on paragraph 7.8 and paragraph 9

Measured at room temperature and standard humidity,

1000pF or less Measurement frequency

Measurement voltage

Over 1000pF

Measurement voltage

Measurement frequency

Based on paragraph 7.6

Measurement is made after rated voltage is applied for 60

±

5s.

Based on paragraph 7.1

Apply 300% of the rated voltage for 1 to 5s then measure.

The temperature coefficients in table 12, paragraph 7.12 are

calculated at 20

C

and high temperature.

Based on paragraph 8.11. 2.

Apply 5N (0.51 kg

f) for 10

±

1s in the

direction indicated by the arrow.

Capacitor

Test board

Pressure (5N)

Chip is mounted to a board in the manner

shown on the right, subjected to vibration

(type A in paragraph 8.2), and measured

24

±

2 hrs. later.

Board

Based on paragraph 8.13

Soldering temperature

Soldering time

Based on paragraph 8.14.

Soldering temperature

Soldering time

Preheating

Based on paragraph 9.3

Number of cycles: 10

Capacitance measured after 24

±

2 hrs.

Test temperature

Relative humidity

Applied voltage

Test time

Capacitance measured after 24

±

2 hrs.

Based on paragraph 9.9

Test temperature

Applied voltage

Test time

Capacitance measured after 24

±

2 hrs.

Based on paragraph 9.10

Class 1 (For thermal compensation)

: 1

±

0.1MHz

: 1

±

0.1Vrms.

: 1

±

0.1kHz

: 1

±

0.1Vrms.

: 235

±

5

C

: 2

±

0.5s

: 260

±

5

C

: 5

±

0.5s

: 150

±

10

C

for 1 to 2 min.

: 40

±

2

C

: 90% to 95%

: rated voltage

: 500 to 524 hrs.

: Max. operating temp.

: rated voltage x 200%

: 1,000 to 1,048 hrs.

*The design and specifications are subject to change without prior notice. Before ordering or using, please check the latest technical specification.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MCH183AN103CC | 1608(0603)Size chip capacitors |

| MCH183AN103CK | 1608(0603)Size chip capacitors |

| MCH183AN103CL | 1608(0603)Size chip capacitors |

| MCH183AN103DC | 1608(0603)Size chip capacitors |

| MCH183AN103DK | 1608(0603)Size chip capacitors |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MCH152A103C | 制造商:ROHM 制造商全稱:Rohm 功能描述:1005(0402)Size chip capacitors |

| MCH152A103D | 制造商:ROHM 制造商全稱:Rohm 功能描述:1005(0402)Size chip capacitors |

| MCH152A103J | 制造商:ROHM 制造商全稱:Rohm 功能描述:1005(0402)Size chip capacitors |

| MCH152A103K | 制造商:ROHM 制造商全稱:Rohm 功能描述:1005(0402)Size chip capacitors |

| MCH152A103Z | 制造商:ROHM 制造商全稱:Rohm 功能描述:1005(0402)Size chip capacitors |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。