- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄383480 > MAX6627MKA-T (MAXIM INTEGRATED PRODUCTS INC) Remote 【1∑C Accurate Digital Temperature Sensors with SPI-Compatible Serial Interface PDF資料下載

參數(shù)資料

| 型號(hào): | MAX6627MKA-T |

| 廠商: | MAXIM INTEGRATED PRODUCTS INC |

| 元件分類: | 溫度/濕度傳感器 |

| 英文描述: | Remote 【1∑C Accurate Digital Temperature Sensors with SPI-Compatible Serial Interface |

| 中文描述: | DIGITAL TEMP SENSOR-SERIAL, 12BIT(s), 5.50Cel, RECTANGULAR, SURFACE MOUNT |

| 封裝: | MO-178, SOT-23, 8 PIN |

| 文件頁數(shù): | 7/9頁 |

| 文件大小: | 151K |

| 代理商: | MAX6627MKA-T |

Filter high-frequency electromagnetic interference

(EMI) at DXP and DXN with an external 2200pF capaci-

tor connected between the two inputs. This capacitor

can be increased to about 3300pF (max), including

cable capacitance. A capacitance higher than 3300pF

introduces errors due to the rise time of the switched-

current source.

PC Board Layout

1) Place the MAX6627/MAX6628 as close as practical

to the remote diode. In a noisy environment, such

as a computer motherboard, this distance can be

4in to 8in, or more, as long as the worst noise

sources (such as CRTs, clock generators, memory

buses, and ISA/PCI buses) are avoided.

2) Do not route the DXP/DXN lines next to the deflec-

tion coils of a CRT. Also, do not route the traces

across a fast memory bus, which can easily intro-

duce +30

°

C error, even with good filtering.

Otherwise, most noise sources are fairly benign.

3) Route the DXP and DXN traces parallel and close to

each other, away from any high-voltage traces such

as +12VDC. Avoid leakage currents from PC board

contamination. A 20M

leakage path from DXP to

ground causes approximately +1

°

C error.

4) Connect guard traces to GND on either side of the

DXP/DXN traces (Figure 3). With guard traces in

place, routing near high-voltage traces is no longer

an issue.

5) Route as few vias and crossunders as possible to

minimize copper/solder thermocouple effects.

6) When introducing a thermocouple, make sure that

both the DXP and the DXN paths have matching

thermocouples. In general, PC board-induced ther-

mocouples are not a serious problem. A copper

solder thermocouple exhibits 3μV/

°

C, and it takes

approximately 200μV of voltage error at DXP/DXN

to cause a +1

°

C measurement error, so most para-

sitic thermocouple errors are swamped out.

7) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10mil

widths and spacings recommended in Figure 3 are

not absolutely necessary (as they offer only a minor

improvement in leakage and noise), but use them

where practical.

8) Placing an electrically clean copper ground plane

between the DXP/DXN traces and traces carrying

high-frequency noise signals helps reduce EMI.

Twisted Pair and Shielded Cables

For remote-sensor distances longer than 8in, or in par-

ticularly noisy environments, a twisted pair is recom-

mended. Its practical length is 6ft to 12ft (typ) before

noise becomes a problem, as tested in a noisy elec-

tronics laboratory. For longer distances, the best solu-

tion is a shielded twisted pair like that used for audio

microphones. For example, Belden #8451 works well

for distances up to 100ft in a noisy environment.

Connect the twisted pair to DXP and DXN and the

shield to ground, and leave the shield

’

s remote end

unterminated. Excess capacitance at DXN or DXP limits

practical remote-sensor distances (see

Typical

Operating Characteristics

).

For very long cable runs, the cable

’

s parasitic capaci-

tance often provides noise filtering, so the recommend-

ed 2200pF capacitor can often be removed or reduced

in value. Cable resistance also affects remote-sensor

accuracy. A 1

series resistance introduces about

+1/2

°

C error.

M

Remote ±1°C Accurate Digital Temperature

Sensors with SPI-Compatible Serial Interface

_______________________________________________________________________________________

7

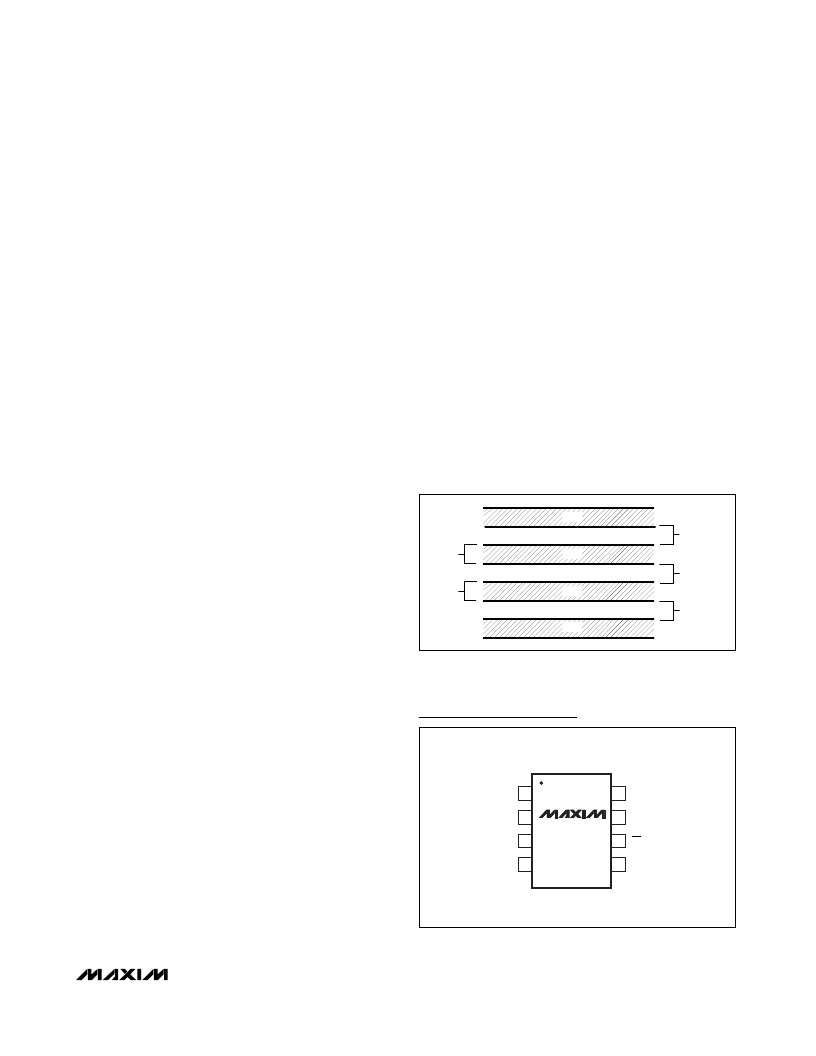

MINIMUM

10mils

10mils

10mils

10mils

GND

DXN

DXP

GND

Figure 3. Recommended DXP/DXN PC Traces

SCK

V

CC

1

2

8

7

N.C.

SO

DXN

DXP

GND

SOT23

TOP VIEW

3

4

6

5

MAX6627

MAX6628

CS

Pin Configuration

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MAX6628MKA-T | Remote 【1∑C Accurate Digital Temperature Sensors with SPI-Compatible Serial Interface |

| MAX6627 | Quadruple 2-Input Exclusive-OR Gates 14-CFP -55 to 125 |

| MAX6630MUT-T | 12-Bit Sign Digital Temperature Sensors with Serial Interface |

| MAX6630 | Decade Counter 14-CDIP -55 to 125 |

| MAX6631 | Decade Counter 14-CDIP -55 to 125 |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MAX6627MTA+ | 制造商:Maxim Integrated Products 功能描述:REMOTE ?1?C ACCURATE DIGITAL TEMPERATURE SENSORS WITH SPI - Rail/Tube |

| MAX6627MTA+T | 功能描述:板上安裝溫度傳感器 1C Accurate Temperature Sensor RoHS:否 制造商:Omron Electronics 輸出類型:Digital 配置: 準(zhǔn)確性:+/- 1.5 C, +/- 3 C 溫度閾值: 數(shù)字輸出 - 總線接口:2-Wire, I2C, SMBus 電源電壓-最大:5.5 V 電源電壓-最小:4.5 V 最大工作溫度:+ 50 C 最小工作溫度:0 C 關(guān)閉: 安裝風(fēng)格: 封裝 / 箱體: 設(shè)備功能:Temperature and Humidity Sensor |

| MAX6628MKA | 制造商:Maxim Integrated Products 功能描述:REMOTE +/- 1-DEGREE C ACCURATE DIGITAL TEMPER - Bulk |

| MAX6628MKA+ | 制造商:Maxim Integrated Products 功能描述:TEMP SENSOR DGTL 3-WIRE/SPI 8PIN SOT-23 - Rail/Tube |

| MAX6628MKA+T | 制造商:Maxim Integrated Products 功能描述:TEMP SENSOR DGTL 3-WIRE/SPI 8PIN SOT-23 - Tape and Reel |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。