- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄359626 > LDEEA2120 (Electronic Theatre Controls, Inc.) PEN-PET H.T PDF資料下載

參數(shù)資料

| 型號(hào): | LDEEA2120 |

| 廠商: | Electronic Theatre Controls, Inc. |

| 英文描述: | PEN-PET H.T |

| 中文描述: | 筆聚酯羥色胺 |

| 文件頁(yè)數(shù): | 7/8頁(yè) |

| 文件大?。?/td> | 499K |

| 代理商: | LDEEA2120 |

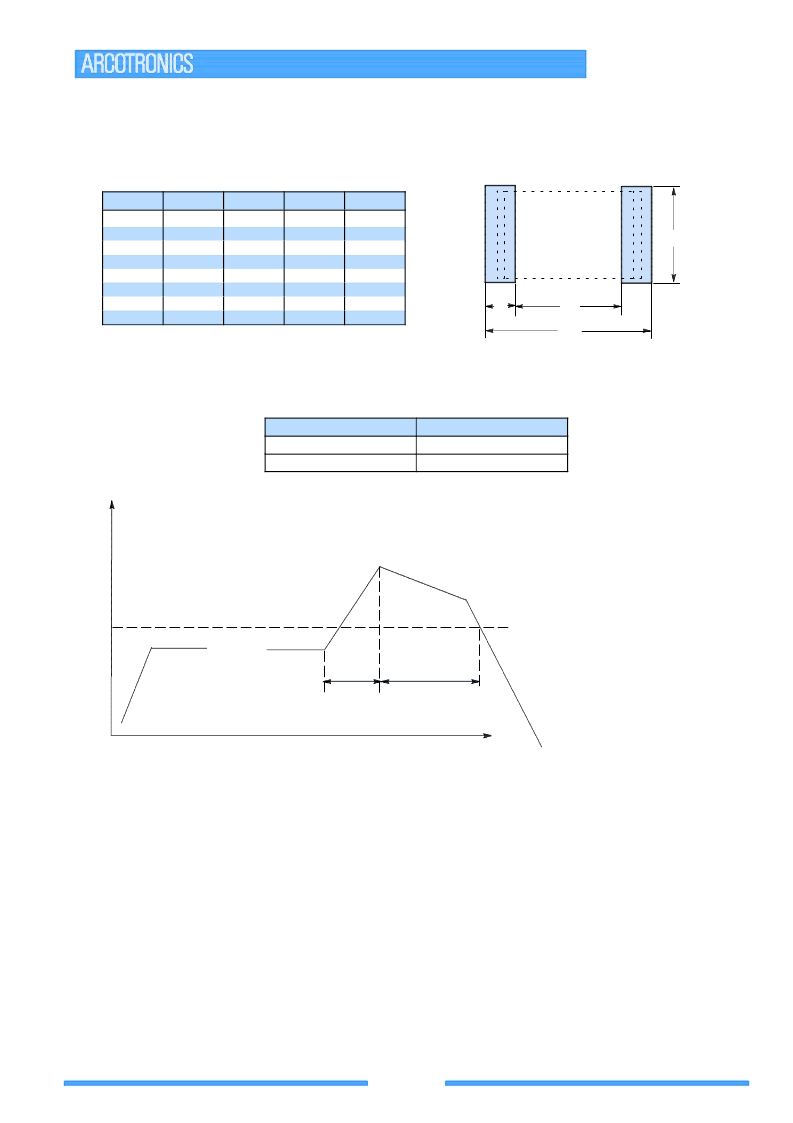

MOUNTING AND SOLDERING

In order to reach a good solderability, we suggest these rules are followed:

S

Landing area

Land dimensions

Size

1206

1210

1812

2220

2824

4030

5040

6054

A

2.0

3.0

4.0

5.9

7.0

8.6

11.2

14.6

B

1.3

1.3

1.5

1.9

2.5

3.0

3.5

3.6

C

2.4

2.4

3.5

4.5

5.7

8.0

10.3

12.6

D

5.0

5.0

6.5

8.3

10.7

14.0

17.3

19.8

S

Solder paste & quantity

To obtain the best performance we advise to use a solder paste alloy TIN (Sn) - LEAD (Pb) - SILVER (Ag) (typical

values 62% - 36% - 2%) of no clean type. The thickness of solder paste is also important, and from our experience we

suggest the following rule:

Size

from 12.06 to 22.20

from 28.24 to 60.54

Thickness [mm]

0.1 to 0.15

0.1 to 0.20

S

Thermal profile

200°C

preheating

time

τ

1

τ

2

T

max

Temperature

Preheating

: Temperature = 150 to 160°C

Time

= 3 min

Peak

:

Max time above 200°C

40 to 50 s and

τ

1

τ

2

T

max

:

from 12.06 to 22.20 T

max

= 225°C

from 28.24 to 60.54 T

max

= 235°C

MOISTURE BARRIER BAG (MBB)

Materials

The MBB is made by three layers: PET, Aluminium and PE for a total thickness of 105

μ

m

S

Moisture resistance

From size 12.06 to 60.54 Arcotronics has tested reels inside this MBB in different extreme conditions

(i.e.: T = 60°C R.H. = 95% 56 days).

The result is: THE CAPACITANCE DOESN’T PRESENT ANY SIGNIFICATIVE CHANGE.

S

Use

After the opening of the MBB the permanence at a temperature

30°C and R.H.

60% is allowed for a maximum lapse

of time of 4 weeks.

For longer times and/or higher T and R.H. values, it is absolutely indispensable to protect the component against R.H.

S

If the reel is partially used, Arcotronics recommend the re-use of the same MBB or a storage in areas with controlled

temperature and humidity.

Storage

The minimum MBB shelf life is 12 months.

S

LDE Series

PEN -- PET H.T.

C

D

A

B

Example for land dimensions

7

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| LDEEA2150 | PEN-PET H.T |

| LDEEB2180 | PEN-PET H.T |

| LDEEB2220 | PEN-PET H.T |

| LDEEB2270 | PEN-PET H.T |

| LDEEB2330 | LED YELLOW CLEAR 1206 REV MT SMD |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| LDEEA2150 | 制造商:未知廠家 制造商全稱(chēng):未知廠家 功能描述:PEN-PET H.T |

| LDEEB2180 | 制造商:未知廠家 制造商全稱(chēng):未知廠家 功能描述:PEN-PET H.T |

| LDEEB2220 | 制造商:未知廠家 制造商全稱(chēng):未知廠家 功能描述:PEN-PET H.T |

| LDEEB2220JA0N00 | 功能描述:薄膜電容器 100volts 0.022uF 5% RoHS:否 制造商:Cornell Dubilier 產(chǎn)品類(lèi)型: 電介質(zhì):Polyester 電容:0.047 uF 容差:10 % 電壓額定值:100 V 系列:225P 工作溫度范圍:- 55 C to + 85 C 端接類(lèi)型:Radial 引線間隔:9.5 mm |

| LDEEB2270 | 制造商:未知廠家 制造商全稱(chēng):未知廠家 功能描述:PEN-PET H.T |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。