- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄370584 > HIP5600 (Harris Corporation) Thermally Protected High Voltage Linear Regulator PDF資料下載

參數(shù)資料

| 型號: | HIP5600 |

| 廠商: | Harris Corporation |

| 英文描述: | Thermally Protected High Voltage Linear Regulator |

| 中文描述: | 熱保護的高電壓線性穩(wěn)壓器 |

| 文件頁數(shù): | 7/16頁 |

| 文件大小: | 175K |

| 代理商: | HIP5600 |

7

junction. With no heat sink C

S

equals zero and

θ

SA

equals the

difference between

θ

JA

and

θ

JC

. The following equations pre-

dict the transient junction temperature and the time to thermal

shutdown for ambient temperatures up to +85

o

C and power

levels up to 8W. The output current limit temperature coeffi-

cient (Figure 39) precludes continuous operation above 8W.

For the TO-220, C

P

is 0.9Ws to 1.1Ws per degree compared

to about 2.6mWs per degree for the integrated circuit and C

S

is 0.9Ws per degree per gram for aluminum heat sinks.

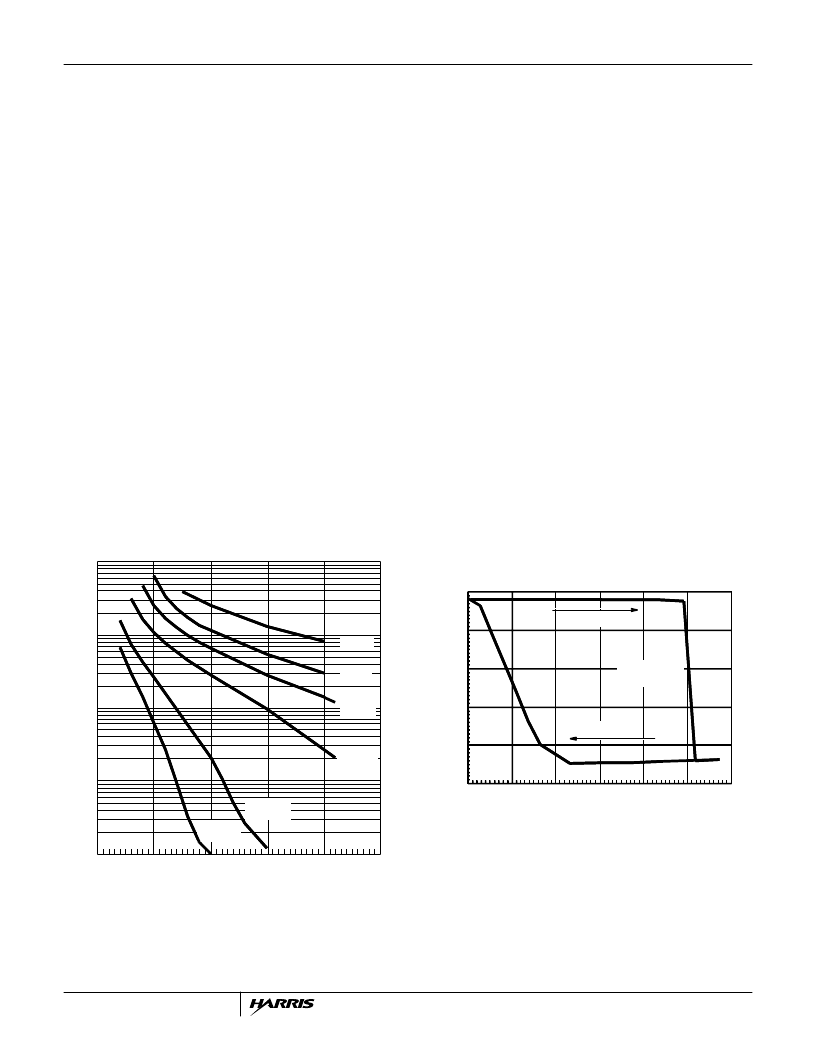

Figure 8 shows the time to thermal shutdown versus power

dissipation for a part in +22

o

C still air and at various elevated

ambient temperatures with a

θ

SA

of +27

o

C/W from forced air

flow.

For the shorter shutdown times, the

θ

SA

value is not impor-

tant but the thermal capacitances are. A more accurate

equation for the transient silicon surface temperature can be

derived from the model shown in Figure 7. Due to the distrib-

uted nature of the package thermal capacitance, the second

time constant is 1.7 times larger than expected.

FIGURE 8. TIME TO THERMAL SHUTDOWN vs POWER

DISSIPATION

Thermal Shutdown Hysteresis

Figure 9 shows the HIP5600 thermal hysteresis curve with

V

IN

= 100V

DC

, V

OUT

= 5V and I

OUT

= 10mA. Hysteresis is

added to the thermal shutdown circuit to prevent oscillations

as the junction temperature approaches the thermal shut-

down limit. The thermal shutdown is reset when the input

voltage is removed, goes negative (i.e. AC operation) or

when the part cools down.

FIGURE 9. THERMAL HYSTERESIS CURVE

AC to DC Operation

Since the HIP5600 has internal high voltage diodes in series

with its input, it can be connected directly to an AC power

line. This is an improvement over typical low current supplies

constructed from a high voltage diode and voltage dropping

resistor to bias a low voltage zener. The HIP5600 provides

better line and load regulation, better efficiency and heat

T

J

t

( )

T

A

P

θ

JC

P

θ

SA

1 e

t

–

τ

----

–

+

+

=

τ

θ

SA

C

P

C

S

+

(

)

≡

Where:

(EQ. 9)

t

τ

ln

–

P

θ

JC

-------------------------------------------------------------------

θ

SA

SA

+

(

)

T

+

T

–

=

(EQ. 10)

T

POWER DISSIPATION (W)

+22

o

C

+70

o

C

+85

o

C

+115

o

C

+120

o

C

+100

o

C

10

2

10

1

10

0

10

10

-2

0.0

2.0

4.0

6.0

8.0

10

TJt

( )

TA

T1

T2

T3

+

+

+

=

T3

0.6P

θ

JC1 e

t

–

τ

3

-------

–

≡

T2

0.4P

θ

JC1 e

t

–

τ

2

-------

–

≡

T1

P

θ

SA1 e

t

–

τ

1

-------

–

≡

τ

1

θ

SACP

CS

+

(

)

≡

τ

2

0.7

θ

JC

-----------------------------------------------------------

+

+

(

≡

τ

3

0.6

θ

JCCD

≡

(EQ. 11C)

(EQ. 11D)

Where:

Where:

Where:

(EQ. 11B)

(EQ. 11A)

CASE TEMPERATURE (

o

C)

I

O

HEATING

SHUTDOWN

REGION

COOLING

10

8.0

6.0

4.0

2.0

0.0

98.0

105.0

113.0

120

127

135

142

HIP5600

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HIP8112A | NTSC/PAL Video Decoder |

| HIR19-21C | Technical Data Sheet 0.8mm Height Flat Top Infrared LED |

| HIR19-L11 | Technical Data Sheet 0.8mm Height Flat Top Infrared LED |

| HIR204C | 3mm Infrared LED, T-1 |

| HIR | 5mm Infrared LED, T-1 3/4 |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HIP5600_02 | 制造商:INTERSIL 制造商全稱:Intersil Corporation 功能描述:Thermally Protected High Voltage Linear Regulator |

| HIP5600EVAL1 | 制造商:Harris Corporation 功能描述: |

| HIP5600EVAL2 | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| HIP5600EVAL3 | 制造商:Harris Corporation 功能描述: |

| HIP5600EVAL4 | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。