- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄64890 > FBA1J4BTTE471P (KOA SPEER ELECTRONICS INC) 4 FUNCTIONS, 0.1 A, FERRITE CHIP PDF資料下載

參數(shù)資料

| 型號: | FBA1J4BTTE471P |

| 廠商: | KOA SPEER ELECTRONICS INC |

| 元件分類: | 數(shù)據(jù)傳輸濾波器 |

| 英文描述: | 4 FUNCTIONS, 0.1 A, FERRITE CHIP |

| 封裝: | EIA STD PACKAGE SIZE 0603 |

| 文件頁數(shù): | 3/3頁 |

| 文件大?。?/td> | 61K |

| 代理商: | FBA1J4BTTE471P |

270

KOA Speer Electronics, Inc. Bolivar Drive P.O. Box 547 Bradford, PA 16701 USA 814-362-5536 Fax: 814-362-8883 www.koaspeer.com

Specifications given herein may be changed at any time without prior notice. Please confirm technical specifications before you order and/or use.

11/01/03

FBA

ferrite bead array

environmental applications (continued)

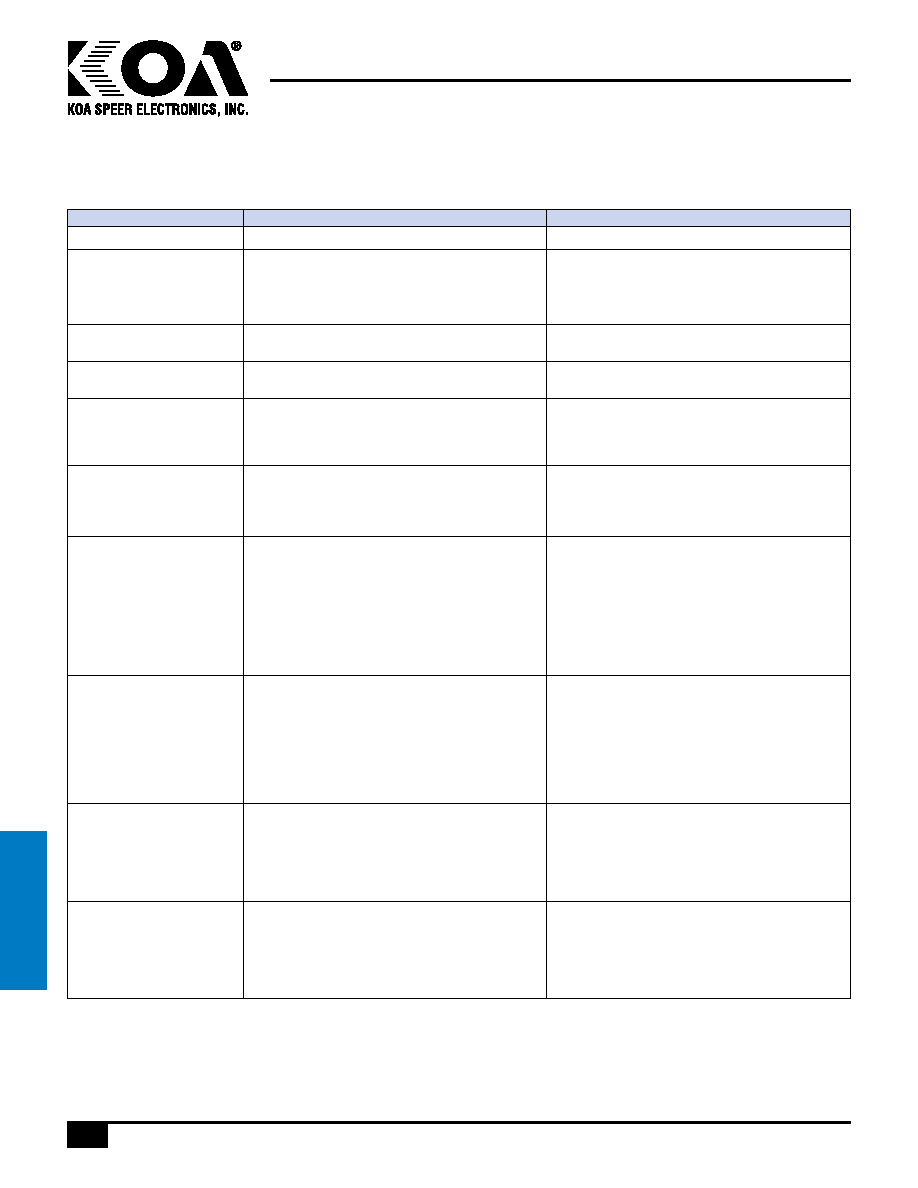

Performance Characteristics

Parameter

Terminal Strength

(hanging test)

Appearance: The terminal electrode shall not break

off, nor shall there be damage to the body.

Type:

W(kgf):

Time:

1206

1.5

30 seconds ± 2 seconds

Terminal Strength

(push test)

Appearance: There shall be no evidence of

mechanical degradations to terminals or body.

Type:

W(kgf):

Time:

1206

2.3

60 seconds

Solvent Resistance

Change in Impedance: Relative to value before

test ±10%

Cleaning by:

Washer: Ultrasonic washer (100W)

Solvent: Isopropyl alcohol

Time: 3 minutes

Insulation Resistance

Insulation Resistance: Min. 1G ohms

Requirement

Test Method

Bending Strength

Appearance: There shall be no physical

or mechanical damage.

Impedance: Relative to initial value

before test ±10%

Board: 90 x 40 x 1.6mm

Bend: 1mm

Time: 5 sec

Mechanical Shock

Appearance: There shall be no physical

or mechanical damage.

Impedance: Relative to initial value

before test ±10%

Force: 50G

Time: 11 msec

There shall be 3 shocks in each of 6 directions

(18 shocks total)

Vibration

Impedance: Relative to initial value ±10%

Only endurance conditioning by sweeping shall

be made. The entire frequency range from

10 - 2,000 Hz, return to 10 Hz in 20 minutes

(this will constitute one cycle).

Amplitude: 15G

The test shall have a 15G peak and shall be

applied for a period of 4 hours (12 cycles) in each

of 3 mutually perpendicular directions (a total of

36 cycles within a total of 12 hours).

Thermal Shock

Appearance: There shall be no physical

or mechanical damage.

Impedance: Relative to initial value ±20%

DCR: The DCR shall not exceed initial specified value.

Testing of the parts will be made at 0 hours, 250

hours and 500 hours. Before testing, the parts shall

be allowed to cool to room temperature for 24 hours.

Step:

Temperature:

Time:

1-start

-40°C ± 2°C

—

2-hold

-40°C ± 2°C

30 minutes ± 5 minutes

3-transfer

—

0.5 minutes maximum

4-hold

±105°C ± 2°C

30 minutes ± 5 minutes

5-transfer

—

0.5 minutes maximum

Steps 1 thru 5 constitute one complete cycle and the

test shall consist of a total of 500 cycles.

Load Humidity

Appearance: There shall be no physical

or mechanical damage.

Impedance: Relative to initial value ±15%

Measurements shall be taken at 0 hours, 250 hours,

500 hours and 1,000 hours and shall meet the

conditions stated above.

Temperature: ±85°C ± 2°C

Relative Humidity: 85%

Time: 1,000 hours total

Apply: 100% rated current

Life Test

Appearance: There shall be no physical

or mechanical damage.

Impedance: Relative to initial value ±15%

Measurements shall be taken at 0 hours, 250 hours,

500 hours and 1,000 hours and shall meet the

conditions stated above.

Temperature: ±85°C ± 2°C

Time: 1,000 hours total

Apply: 100% rated current

EMI/EMC

filtering

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| FBF325 | 1 FUNCTIONS, 114.99 MHz, SAW FILTER |

| FBF331 | 1 FUNCTIONS, 160 MHz, SAW FILTER |

| FBF334 | 1 FUNCTIONS, 70 MHz, SAW FILTER |

| FBF334 | 1 FUNCTIONS, 70 MHz, SAW FILTER |

| FBG403 | 1 FUNCTIONS, 70 MHz, SAW FILTER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| FBA1J4BTTE600P | 制造商:KOA 制造商全稱:KOA Speer Electronics, Inc. 功能描述:ferrite bead array |

| FBA1J4BTTE601P | 制造商:KOA 制造商全稱:KOA Speer Electronics, Inc. 功能描述:ferrite bead array |

| FBA-24-ALE-050 | 制造商:American Technical Ceramics Corp 功能描述: |

| FBA-24-ALE-060 | 制造商:American Technical Ceramics Corp 功能描述: |

| FBA42060 | 功能描述:功率因數(shù)校正 IC PFC SPM 45Series for 1-Phase Boost PFC RoHS:否 制造商:Fairchild Semiconductor 開關(guān)頻率:300 KHz 最大功率耗散: 最大工作溫度:+ 125 C 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:SOIC-8 封裝:Reel |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。