- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄374178 > CSR09B565MD (KEMET Corporation) TANTALUM HERMETICALLY SEALED / AXIAL PDF資料下載

參數(shù)資料

| 型號: | CSR09B565MD |

| 廠商: | KEMET Corporation |

| 英文描述: | TANTALUM HERMETICALLY SEALED / AXIAL |

| 中文描述: | 鉭密封/軸流 |

| 文件頁數(shù): | 72/84頁 |

| 文件大小: | 590K |

| 代理商: | CSR09B565MD |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁當前第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁

KEMET

PACKAGING INFORMATION

72

KEMET Electronics Corporation, P.O. Box 5928, Greenville, S.C. 29606 (864) 963-6300

KEMET offers Solid Tantalum Capacitors fully compatible for use with automatic insertion machines for radial-lead components. Aris Reeling meets

all requirements of EIA Standard RS-468. KEMET capacitors are wound on a precision made ARIS Reel Package. ARIS Ammo Package is also available.

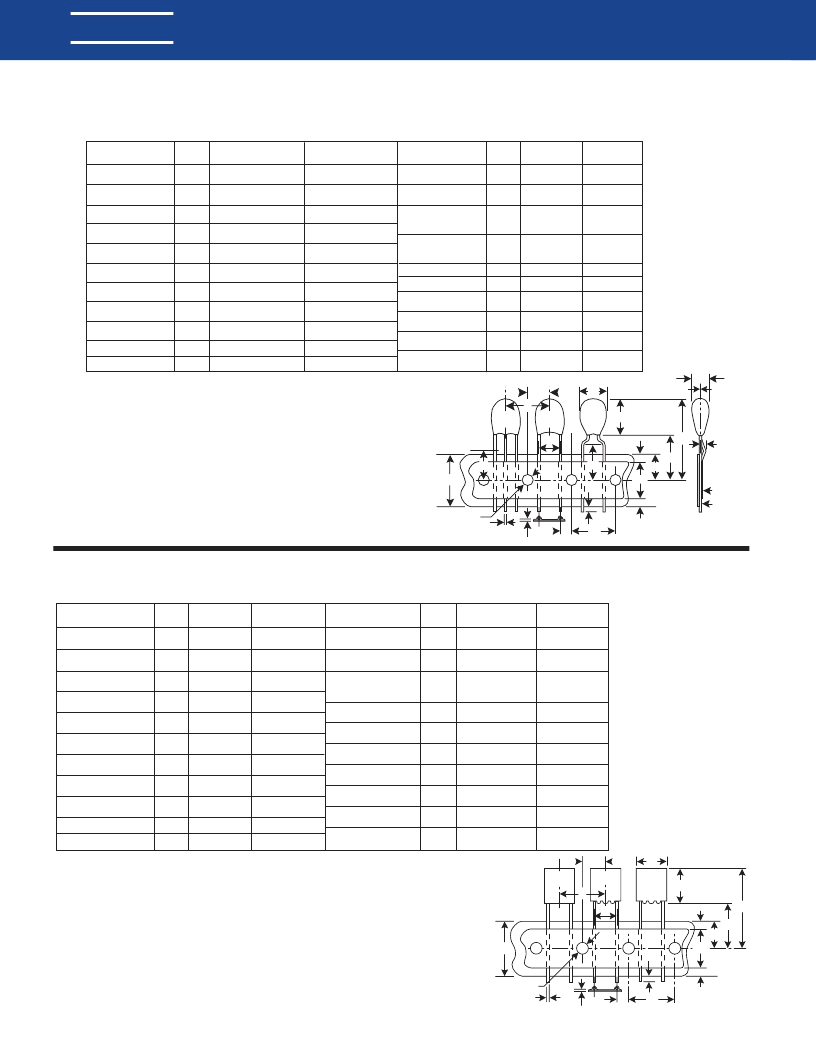

Tantalum Dipped Radial – ARIS Specification (Automatic Radial Insertion System)

Tantalum Dipped Tape and Reel Dimensions in Millimeters & (Inches)

Tantalum Molded Radial – ARIS Specification (Automatic Radial Insertion System)

Tantalum Molded Tape and Reel Dimensions in Millimeters & (Inches)

On polar devices, the positive (+) lead exits from container first.

** Lead spacings are 5.0mm (.197") center-to-center.

On polar devices, the positive (+) lead exits from container first.

* Lead spacings are 2.5mm (.098") center-to-center (T350 A-H)

** Lead spacings are 5.0mm (.197") center-to-center

F Dimensions:

0.100"

±

.015

0.125"

±

.015

0.200"

±

.015

0.250"

±

.015"

0.100 "

±

.015 (3 leaded)

P1 Dimensions:

Lead

Spacing

0.100" – 0.200

±

.028"

0.125" – 0.187

±

.028"

0.200" – 0.150

±

.028"

0.250" – 0.125

±

.028"

0.100" – 0.100

±

.028" ( 3 leaded)

T330**

T340**

T370

P

2

H

A

W

1

W

0

W

2

W

2

P

0

T

d

L

1

A

1

P

H

1

W

D

0

P

1

F

T350/1*

T352/3/4/5/6**

T396/8*

1MM Max.

Tape

Carrier

T

0

H

P

2

H

A

W

0

W

2

W

2

P

0

T

d

L

1

A

1

P

H

1

W

1

P

1

F

W

D

0

L

H

0

Body Height (1)

Body Width (1)

Sprocket Hole

Diameter

Lead Diameter

Lead Center (5)

Component Base

to Tape Center (2)(4)(6)

Lead Standoff

Height

Component Height

Above Tape Center

Component Alignment

Front to Rear

Cut Out Length

Lead Protrustion

Dimension

Symbol

A

Nominal

mm (inch)

10.50 (.413)

Tolerance

mm (inch)

±

.38 (

±

.015)

Maximum

Maximum

±

.38

±

(.015)

±

0.3 (

±

.012)

Dimension

Component Pitch (5)

Symbol

P

Nominal

mm (inch)

12.7 (.500)

Tolerance

mm (inch)

±

1.0 (

±

.039)

Sprocket Hole

Pitch (3)

Sprocket Hole

Center to Lead

Center (4) (5)

Sprocket Hole Center

to Component Center

Body Thickness

Total Tape Thickness

Carrier Tape Width

Hold-Down Tape

Width

Sprocket Hole

Location

Hold-Down Tape

Location

A1

D0

d

F

H

H0

H1

H

L

L1

15.24 (.600)

4.0 (.157)

0.51 or 0.64

(.020) (.025)

5.0 2.5

(.197) (.098)

18.0 (.709)

N/A

32.25 (1.270)

0

11.0 (.433)

2.0 (.079)

±

0.05 or

±

.03

(

±

.001)

+ 0.8/ - 0.2

(+ .032/ -.008)

Reference Only

Maximum

±

2.0

(

±

.079)

Maximum

Maximum

12.7 (.500)

3.85 4.76 5.1

(.152) (.188) (.201)

6.35 (.250)

6.35 (.250)

0.7 (0.28)

18.0 (.709)

15 or 6

(.561) (.236)

9.0 (.354)

3.0 or 12.0

(.118) (.472)

P0

P1

P2

T0

T

W

W0

W1

W2

±

0.3 (

±

.012)

±

0.7 (

±

.028)

±

1.3 (

±

.051)

±

1.3 Maximum

±

.02 (

±

.008)

+ 1.0/-0.5

(+.039/-.020)

+ 1.0/-0.8

(+.039/.031)

+.075/-0.5

(+.030/-.020)

Maximum

Notes: (1) See page 50 for T330, page 53 for T340 and page 59 for T35X specific dimensions.

(2) Reference Only

(3) Cumulative pitch error

±

1.0mm (.039") maximum in 20 consecutive sprocket hole locations.

(4) Measured at bottom of standoff.

(5) P, P1 and F measured at egress from carrier tape.

(6) H dimensions for T370 D and E 16.5mm

±

0.5mm (0.650"

±

0.020")

Body Height (1)

Body Width (1)

Sprocket Hole

Diameter

Lead Diameter

Lead Center (4)

Component Base

to Tape Center (4)

Lead Standoff

Height

Component Height

Above Tape Center

Component Alignment

Front to Rear

Cut Out Length

Lead Protrustion

Notes: (1) See page 62 for T35X and page 69 for T39X specific dimensions.

(2) Cumulative pitch error

±

1.0mm (.039) maximum in 20 consecutive sprocket hole locations.

(3) Measured at bottom of standoff.

(4) P1 and F measured at egress from carrier tape.

(5) P and P2 measured at egress from carrier tape.

Dimension

Symbol

A

Nominal

mm (inch)

Tolerance

mm (inch)

Dimension

Component Pitch (5)

Symbol

P

Nominal

mm (inch)

12.7 (.500)

Tolerance

mm (inch)

±

1.0 (

±

.039)

Sprocket Hole

Pitch (2)

Sprocket Hole

Center to Lead

Center (3) (4)

Sprocket Hole Center

to Component (5)

Center

Body Thickness

Total Tape Thickness

Carrier Tape Width

Hold-Down Tape

Width

Sprocket Hole

Location

Hold-Down Tape

Location

A1

D0

d

F

H

H0

H1

H

L

L1

17.0 (0.67)

10.2 (0.40)

4.0 (.157)

0.51 or 0.64

(.020) (.025)

See Note Below

C-7301 C-7303

16.0 (.630) 18.0 (.709)

C-7301 C-7303

16.0 (.630) 18.0 (.709)

32.25 (1.270)

0

11.0 (.433)

1.0 (.039)

Maximum

Maximum

±

0.3 (

±

.012)

±

0.05 (.002)

C-7301 C-7303

±

0.5 (

±

.020) Minimum

C-7301 C-7303

±

0.5 (

±

.020) Minimum

Maximum

1.0 (.039)

Maximum

Maximum

12.7 (.500)

See Note

Below

See Note

Below

10.2 (.400)

0.7 (0.28)

18.0 (.709)

15mm or 6mm

(.561) (.236)

9.0 (.354)

12mm (.472)

P0

P1

P2

T0

T

W

W0

W1

W2

±

0.3 (

±

.012)

±

0.7 (

±

.028)

Maximum

±

.02 (.008)

+ 1.0/-0.5

(+.039/-.020)

+ 1.0/-0.8

(+.039/-.031)

+.075/-0.5

(+.030/-.020)

Maximum

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| CSR09B565MM | TANTALUM HERMETICALLY SEALED / AXIAL |

| CSR09B565MP | TANTALUM HERMETICALLY SEALED / AXIAL |

| CSR13B565JR | TANTALUM HERMETICALLY SEALED / AXIAL |

| CSR13B565JS | TANTALUM HERMETICALLY SEALED / AXIAL |

| CSR13B565KM | TANTALUM HERMETICALLY SEALED / AXIAL |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| CSR09B565MM | 制造商:KEMET 制造商全稱:Kemet Corporation 功能描述:TANTALUM HERMETICALLY SEALED |

| CSR09B565MP | 制造商:KEMET 制造商全稱:Kemet Corporation 功能描述:TANTALUM HERMETICALLY SEALED |

| CSR09B565MR | 制造商:KEMET 制造商全稱:Kemet Corporation 功能描述:TANTALUM HERMETICALLY SEALED |

| CSR09B565MS | 制造商:KEMET 制造商全稱:Kemet Corporation 功能描述:TANTALUM HERMETICALLY SEALED |

| CSR09C106JB | 制造商:KEMET Corporation 功能描述:LOADED FOR CROSS REF. ONLY MIL PN: M39003/02-2009 - Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復。