- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄384068 > μPD98408 (NEC Corp.) ATM Physical Interface(ATM 物理接口) PDF資料下載

參數(shù)資料

| 型號: | μPD98408 |

| 廠商: | NEC Corp. |

| 英文描述: | ATM Physical Interface(ATM 物理接口) |

| 中文描述: | ATM物理接口(自動柜員機物理接口) |

| 文件頁數(shù): | 30/32頁 |

| 文件大?。?/td> | 193K |

| 代理商: | ΜPD98408 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁當前第30頁第31頁第32頁

30

μ

PD98408

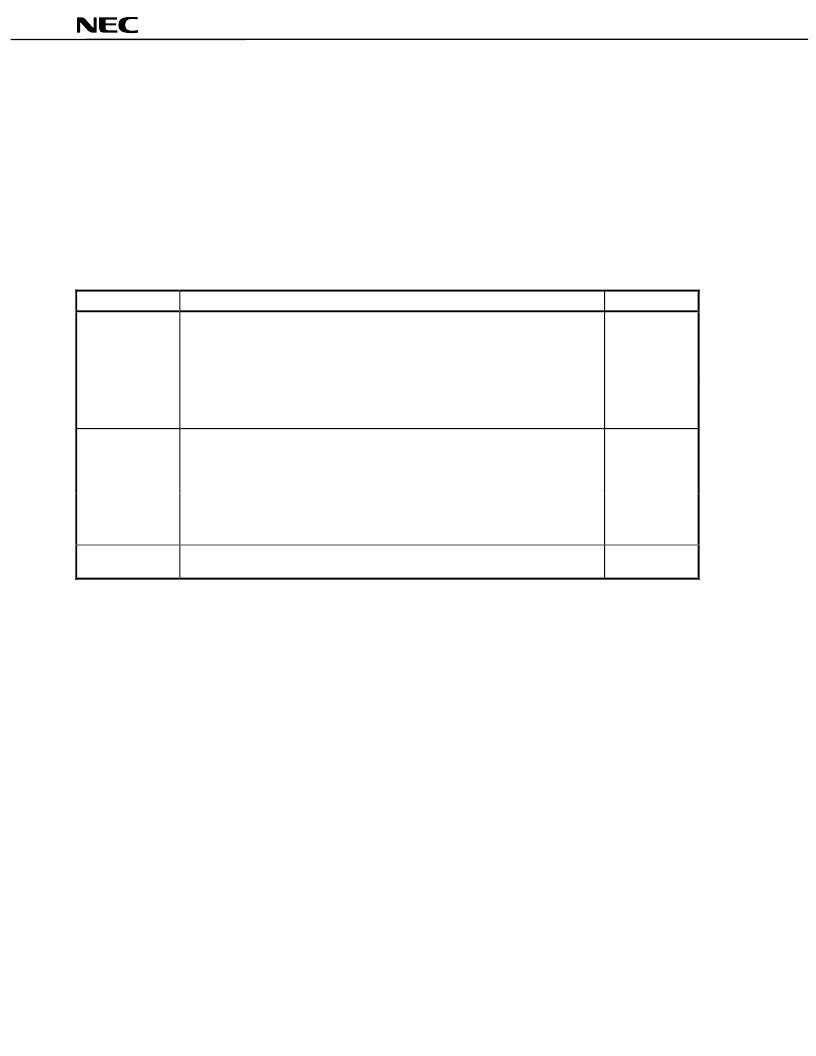

4. RECOMMENDED SOLDERING CONDITIONS

The conditions listed below shall be met when soldering the

μ

PD98408.

For details of the recommended soldering conditions, refer to our document

Semiconductor Device Mounting

Technology Manual (C10535E)

.

Please consult with our sales offices in case any other soldering process is used, or in case soldering is done

under different conditions.

Surface-Mount Type

μ

PD98408GD-LML: 208-pin plastic QFP (fine pitch) (28

×

28 mm)

Soldering Process

Soldering Conditions

Symbol

Infrared ray reflow

Peak package's surface temperature: 235

°

C

Reflow time: 30 seconds or less (210

°

C or more)

Maximum allowable number of reflow processes: 2

Exposure limit: 7 days

Note

(36 hours of pre-baking is required at 125

°

C afterward)

IR35-367-2

<Caution>

Non-heat-resistant trays, such as magazine and taping trays, cannot be baked before

unpacking.

VPS

Peak package's surface temperature: 215

°

C

Reflow time: 40 seconds or less (200

°

C or more)

Maximum allowable number of reflow processes: 2

Exposure limit: 7 days

Note

(36 hours of pre-baking is required at 125

°

C afterward)

VP15-367-2

<Caution>

Non-heat-resistant trays, such as magazine and taping trays, cannot be baked before

unpacking.

Partial heating

method

Terminal temperature: 300

°

C or less

Heat time: 3 seconds or less (for one side of a device)

Note

Maximum number of days during which the product can be stored at a temperature of 25

°

C and a relative

humidity of 65 % or less after dry-pack package is opened.

Caution

Do not apply two or more different soldering methods to one chip (except for partial heating

method for terminal sections).

相關PDF資料 |

PDF描述 |

|---|---|

| μPD98411 | Ultraframer DS3/E3/DS2/E2/DS1/E1/DS0 |

| μPD98501 | Network Controller(網(wǎng)絡控制器) |

| μPG103B | Wide-Band Amplifier(寬帶放大器) |

| μPG110B | 2 to 8 GHz WIDE BAND AMPLIFIER(2-8GHz 寬帶放大器) |

| μPG132G | L-Band SPDT Switch(長波段單刀雙擲開關) |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| PD98CNT30QMU | 制造商:Carlo Gavazzi 功能描述:PHOTO TS PL 30M AC/DC NO+NC |

| PD9909-59 | 制造商:Philco/Philips 功能描述: |

| PD9930-51 | 制造商:Philco/Philips 功能描述: |

| PD9933-59 | 制造商:Philco/Philips 功能描述: |

| PD9941-59 | 制造商:Philco/Philips 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復。