Product Data Sheet

3M Moisture Barrier Bag Dri-Shield 2000

3M Moisture Barrier Bag Dri-Shield 2000

Product Data Sheet

This aluminized moisture barrier bag is designed to provide a static safe environment

for sensitive electronic devices. The bags are heat sealable and suitable for vacuum

packaging. Bags are printed with ESD and moisture warning symbols and a lot code

for traceability.

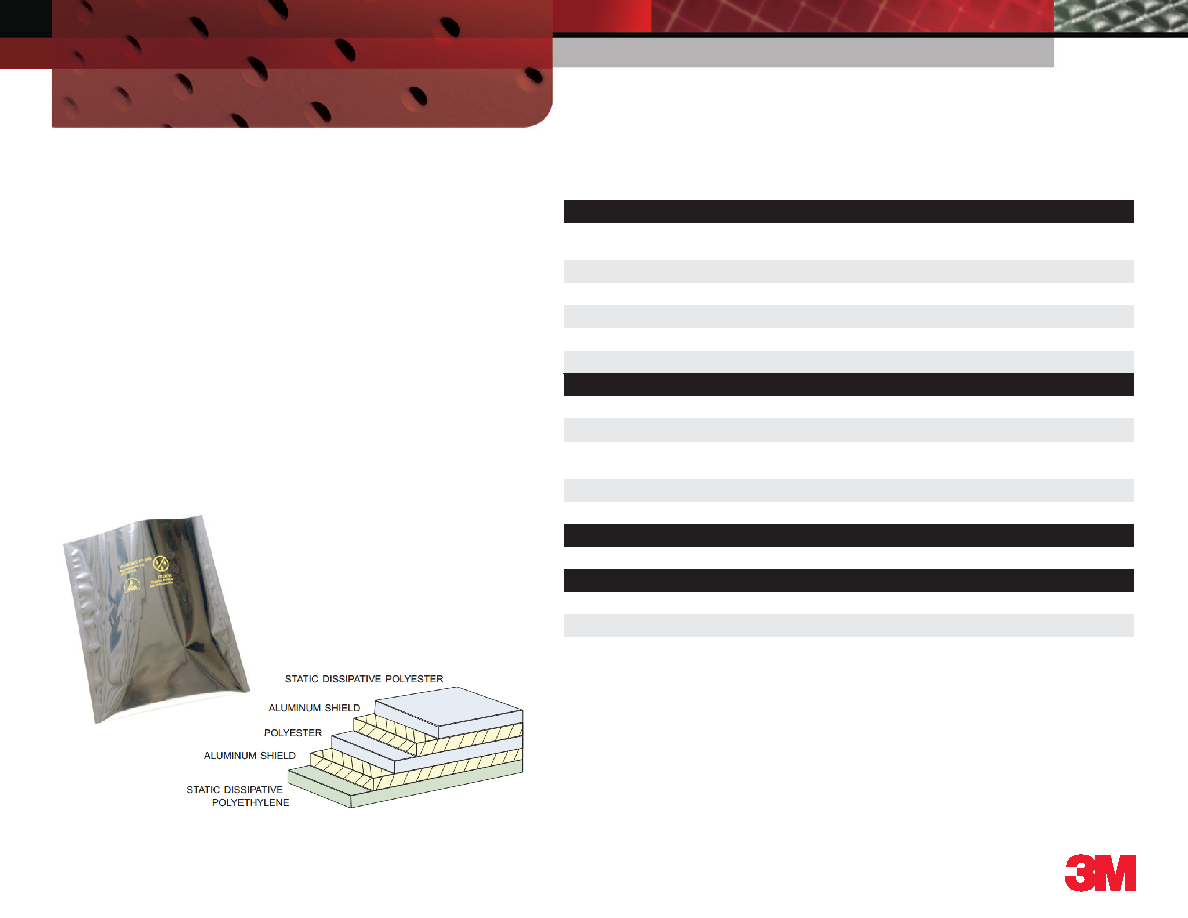

3M Moisture Barrier Bags Dri-Shield 2000 are manufactured from a laminate of

multiple layers of aluminized polyester and polyethylene. Polyester provides puncture

resistance. Metal layers are intended to provide shielding of Electrostatic Discharge

(ESD) and to help minimize the penetration of electric field.

These bags are tested to meet or exceed certain electrical and physical requirements

of ANSI/ESD S541, and to be ANSI/ESD S20.20 program compliant. Bags are RoHS

Compliant* and lead-free**.

Physical

Typical Values

Testing Method

Moisture Vapor Transmission

Rate (MVTR)

0.035 grams/100 sq. in./24 hrs.1

MIL-STD-3010C Method 3030

Tensile Strength

7800 PSI, 54 MPa

ASTM D882

Puncture Resistance

20 lbs, 89 N

MIL-STD-3010C Method 2065

Seal Strength

15 lbs, 66N

ASTM D882

Thickness

3.6 mils, .0914 mm +/-15%

MIL-STD-3010C Method 1003

Marking Adhesion

Pass

IPC-TM-650 2.4.1

Electrical

Typical Values

Testing Method

ESD Shielding

<10 nJ

ANSI/ESD STM11.31

Surface Resistance - Interior <1x1011 ohms

ANSI/ESD STM11.11

Surface Resistance -

Exterior

<1x1011 ohms

ANSI/ESD STM11.11

Static Decay

< 2 seconds

ETS 406D

EMI Attenuation

45 dB

1 to 10 GHz

Cleanliness

Typical Values

Testing Method

Silicone

Not Detected

FTIR

Heat Sealing Conditions

Typical Values

Temperature

300°F - 400°F, 140°C - 204°C

Time

0.6 - 4.5 seconds

Pressure

30 - 70 PSI, 206 - 482 KPa

3M Moisture Barrier Bag

Dri-Shield 2000

1

Standard deviation of 0.008 grams/100 sq. in./24 hrs.

This product is intended for commercial use only. This product is not on the Qualified Product

Listing under the Defense Standardization Program.